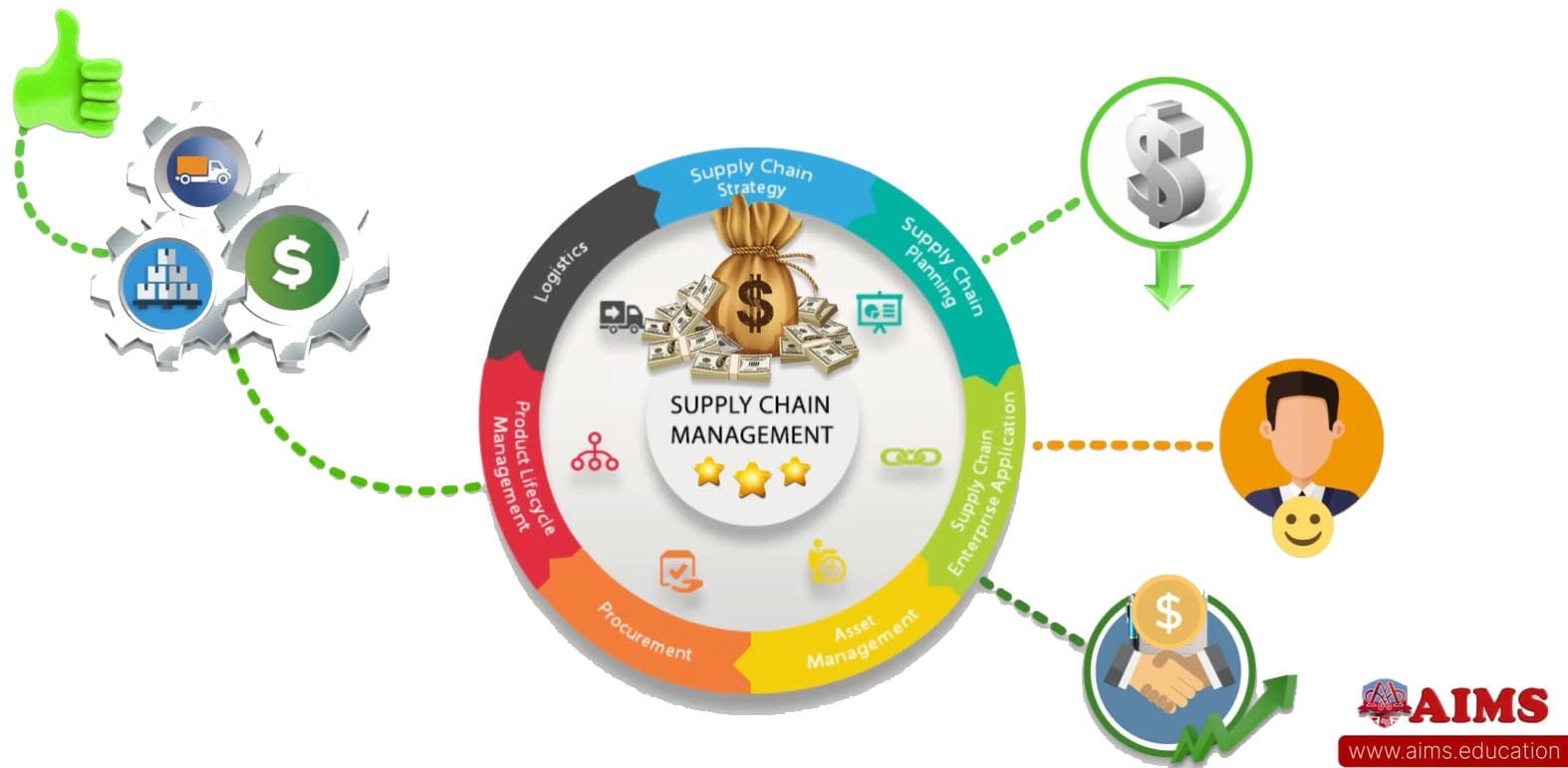

All of us can enjoy a wide variety of products due to the advancement in technology and supply chains. But, even so, a supply cannot be effective and deliver up to the expectancies of end consumers without a proper management system. The importance of supply chain management is larger than usually seen, as it makes sure that people get their favorite products when they need them, taking care of the elementary steps that begin with obtaining the raw matter and ending with taking the finished product to store shelves or client’s front door. However, its management is not the task of a single person whether it is a huge enterprise or a small business. A well-managed team can make it successful. The most important role is played by the manager who maintains the supply chain of the company. The role of supply chain management is to assure that the demand of customers is met with the supply of the products. Supply chain roles and responsibilities include the assurance that the companies never produce extra or insufficient products.

Role of Supply Chain Management:

Supply chain management is an integral part of business organizations and important for the success of the company. Due to this reason, demand for supply chain management qualifications is growing worldwide. Considering these demands, AIMS’ supply chain academy offers Certifications, Diploma, online MBA in supply chain management and PhD supply chain management programs. All these are internationally recognized and UK accredited qualifications.

“Due to the rapid advancement in technology, most business organizations are available online. The market is becoming competitive and thus increasing the role of supply chain management”.

Key Supply Chain Roles and Responsibilities:

1. Increase Customer Service:

One of the most important supply chain roles and responsibilities is to manage customer service. The customers should always get what they are looking for. Whether it is a product, a solution to their issues, or answers to their questions. The international supply chain management team as to assure that the customer service platform is accessible 24/7 so the customers will feel connected to the organization they would like to do business with.

2. Reduce Production Cost:

The first and most important thing managers have to do is to reduce the production cost of the items. It is done by:

- Introducing machines in the industry.

- Buy the raw materials directly from the factories or the wholesale markets.

- Reduce the number of rejected or failed items.

- Increasing the efficiency of the workforce.

3. Improve Quality of Products:

It is a fact that the production cost of the products has to be reduced but at the same time, the quality of the items has to be enhanced. It has to be assured that the raw material and manufacturing of the items in high-class because only then customers will be attracted. They have to be durable, reliable, and long-lasting, so they can give the best result in all supply chain management industries.

4. Improve Financial Position:

The company has to improve its financial status. It has to be assured that the customers will return to buy the products once again because they are satisfied with the previous items. The supply chain management has to work in such a way that

- The cash flow of the company will increase.

- The number of fixed assets will decrease.

- The profit leverage will increase.

It will make the customer believe that the company is progressing and showing positive results.

5. Development of Best Marketing Strategies:

The supply chain management team has to develop the best marketing strategies for the company to assure that its products will be present in the best possible way. Customers often decide whether they would buy a certain item or not by looking at the advertisements shared on different platforms.

Role of IT in Supply Chain Management:

IT is used in a variety of ways to improve supply chain management operations. Depending on the needs of individual organizations, IT can take many forms, including data management software, cloud services, mobile devices, and more. In addition to automating processes some more important roles of IT in supply chain management are listed below:

- It helps to streamline operations and improve efficiency, as well as reduce costs.

- It can also help companies build brand awareness and attract new customers by making their products available online.

- It can help companies reduce costs and increase efficiency by automating processes, connecting disparate systems, and building brand awareness among consumers.

- It can ensure security and compliance with regulations.

- It can help to automate processes, provide real-time visibility, automate tracking and traceability, manage risk, optimize logistics and increase inventory accuracy.

- It can help companies to increase sales, reduce inventory levels and improve customer satisfaction.

- It also helps to improve the security of supply chains by helping to protect sensitive data.

“Information Technology can help to automate processes, provide real-time visibility, automate tracking and traceability, manage risk, optimize logistics and increase inventory accuracy. It can help companies to increase sales, reduce inventory levels and improve customer satisfaction. It also helps to improve the security of supply chains by helping to protect sensitive data.”.

Importance of Supply Chain Planning and Control:

Supply chain planning and control is an important part of any business’s operations, especially when it comes to managing large quantities of products. If a company fails to plan ahead, they risk running out of products at inopportune moments, which can lead to significant losses. By contrast, if a business makes sure to have plenty of supplies on hand, it can avoid these kinds of issues.

With that said, supply chain planning and control aren’t easy—especially in large companies. A lot of work needs to be done before things can get off the ground, and there are many different factors that need to be taken into account. For this reason, most businesses use software to help them with this process. By doing so, they can make sure that everything is running smoothly.

Importance of Supply Chain Management in Retail & FMCG:

In Retailing:

- It lowers the costs, as it helps a business deliver the provided products in the fastest manner possible, instead of keeping them in transit for too long;

- A well-built supply chain will gain more clients for your business, pushing it one step further than your competition;

- It can make the provided products more affordable, by lowering the overall costs, but without making your company lose the profit; this will be highly appreciated by your clients;

- Customer services and experiences will be much improved, as customers enjoy prompt and secure delivery of their favorite products;

- It will optimize the processes and make the supplies move faster along the chain, helping your business save time and money and improve its reputation in the eyes of end consumers.

In FMCG:

- It improves the transparency of processes along the supply chain so that FMCG (Fast Moving Consumer Goods) supplies can be tracked easier and delivered with increased efficiency;

- The operations will become much more effective, which is extremely important for the success of an FMCG business;

- It ensures a steady supply of goods where they are needed and when they are needed so that consumers won’t have to face shortages;

- It minimizes losses by optimizing the processes, which is essential considering the volatile nature of some products in the FMCG market;

- It improves coordination between demand and supply, allowing managers to see precisely what is needed, how much, and where it has to be delivered.

Implementation of Supply Chains Systems:

The way we do business today changed a lot. A business can provide products not just on local markets, but also sell them internationally. With the help of today’s technology, it is very easy to globalize with the right supply chain analysis and acquire clients from all over the world. So, supply chains developed a lot in recent years.

- Without a proper management system, a supply chain, regardless of its type, won’t manage to unroll its processes successfully and satisfy the clients of your business. Just how important a management system for a supply chain is?

- A good management strategy will reduce the costs of your supply chain, improve customer services, and generate more sales that will strengthen the financial power of your business.

Before implementing a management system for a supply chain, you need to be aware that there’s the need for proper training, support, and sufficient tests. If you ignore these aspects, there are high chances for the implemented system to fail. Besides these, you need to be well aware that communication is very important as well, as you will need to interview every person involved in different stages of the supply chain.

Key Note!