What is Green Supply Chain Management?

Green Supply Chain Management is the coordination and integration of environment-friendly processes, practices, and technologies into the traditional supply chains. The concept of green supply chain management encompasses the entire lifecycle of a product, from the sourcing of raw materials to its distribution, while minimizing the ecological footprint and reducing elements like emissions, conserving resources, and ensuring eco-friendly practices. Companies adopting green SCM practices often focus on energy efficiency, waste reduction, and recycling initiatives, which ultimately contribute to maintaining better environmental conservation and promoting corporate social responsibility.

Contrast Between Sustainable and Green Supply Chain Management

Green supply chains can be characterized as incorporating ecological intuition into store network administration, including item outline, material sourcing and choice, fabricating forms, conveyance of the last item, and additionally end-of-life administration of the item after its valuable life.

Supportability can be augmented all through the supply chain, starting with idea and advancement then proceeding through all periods of creation and last client dissemination. Articles here spotlight on endeavors by materials suppliers, item producers, and retailers to build supportability. These expanded supportability endeavors are had to diminish the effect of the production network on future eras.

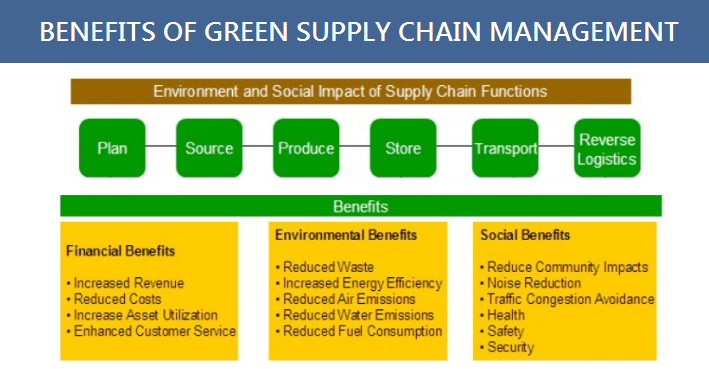

Importance and Benefits of Green Supply Chain Management

- The most basic advantage of the green supply chain is a positive long-haul net effect on the money-related execution of the association.

- Companies receiving Green Supply Chain practices can lessen the danger of being indicted for being hostile to natural and untrustworthy practices.

- At the center of it, is the guideline of decreasing waste by expanding efficiencies.

- Better control of item security and quality.

- They support the successful use of the majority of the accessible beneficial assets of associations.

- Effective connections with environmentally friendly suppliers.

- Large speculations and dangers are shared among supply chain management partners.

- It helps an association to position itself and its items as ecologically amicable in the clients’ discernment.

- Transparency of the green business.

- Increased financial benefits and profits.

- Green supply chain companies that produce items that are mechanically cutting-edge and environment amicable discovered that this will upgrade the brand picture and brand notoriety in clients’ brains.

- Better utilization of waste.

- Dissemination of innovation, propelled procedures, capital, and learning among the chain accomplices.

8 Key Objectives of Green Supply Chain Management

Here are the 8 key objectives and goals of using the Green Supply Chain Management (GSCM):

- Reduction of carbon footprint.

- Implementation and practices of energy-efficient technologies.

- Waste reduction through recycling strategies.

- Ensure that materials are sourced from suppliers who adhere to environmental guidelines.

- Product lifecycle management should have minimal negative impact on the environment.

- Regulatory Compliance and environmental laws should be followed.

- Companies should follow corporate social responsibility.

- Natural resources should be used efficiently while ensuring sustainability.

Let us review each of them in detail:

1. Environmental Protection

By reducing carbon emissions, minimizing waste, and conserving resources, green supply chain management practices protect natural habitats and help in combating climate change.

2. Cost Savings

Enhanced energy efficiency leads to cost savings.

3. Regulatory Compliance

Adhering to environmental regulations and standards helps companies avoid financial supply chain management risks, such as fines and legal penalties.

4. Brand Enhancement

Companies that commit to green supply chain practices often enjoy improved brand reputation and can differentiate their brand in a competitive market.

5. Innovation and Efficiency

Implementing green supply chain practices often encourages materials, and technologies that are environmentally friendly.

6. Market Competitiveness

Green supply chains can open up new markets and opportunities, and following the trend can supply chain management companies position themselves as leaders in sustainability.

7. Employee Satisfaction and Retention

Green SCM can enhance employee morale while demonstrating social responsibility, which can create a positive work environment.

8. Improved Risk Management

GSCM practices mitigate risks associated with resource scarcity, regulatory changes, and environmental disasters. This proactive approach leads to long-term business viability.

This lecture is a part of online educational programs offered by supply chain academy for professionals seeking careers and growth in this field. If you are willing to develop and enhance your skills in supply chain management, then AIMS’ post-graduate diploma in supply chain management and supply chain management online training courses could be your best choice.

How to Convert Your Supply Chain into a Green Supply Chain?

Here are some steps to guide you convert your traditional supply chain into a green supply chain:

1. Conduct a Sustainability Audit

- Start by assessing your current supply chain operations to identify areas with high environmental impact.

- Evaluate energy usage, waste generation, water consumption, and emissions.

- This audit will provide a baseline and help you prioritize actions.

2. Set Clear Sustainability Goals

- Establish sustainability goals to align with your overall business objectives.

- Address the key impact areas identified during the audit.

3. Engage Stakeholders

- Engage internal teams, suppliers, and other stakeholders.

- Communicate the benefits and importance of a green supply chain and encourage everyone’s participation.

4. Redesign Product Life Cycles

- Redesign products that use eco-friendly materials, reducing packaging, and enhancing recyclability.

- Consider the entire product life cycle from sourcing to disposal, aiming for minimal environmental impact.

5. Optimize Logistics and Transportation

- Optimize logistics management to reduce carbon emissions.

- This can involve route optimization, consolidating shipments, using fuel-efficient vehicles, and exploring alternative modes of transport like rail or shipping.

6. Invest in Sustainable Technologies

- Adopt the latest technologies that support sustainable supply chain practices.

- These practices include energy-efficient machinery, renewable energy solutions, waste reduction systems, and digital tools for monitoring and managing environmental impact.

7. Partner with Eco-Friendly Suppliers

- Choose suppliers that share your commitment to sustainability.

- Assess their environmental practices and work together to achieve mutual goals.

- Prefer suppliers with certifications like ISO 14001 environmental management standards.

8. Implement Circular Economy Practices

- Shift towards a circular economy model.

- Develop recycling programs and design durable products for longer life spans.

9. Monitor and Report Progress

- Continuously monitor your progress towards green supply chain goals and report the results.

- Publishing your reports enhances credibility and trust among customers and stakeholders.

10. Continuous Improvement and Innovation

- Regularly review and update your strategies, stay informed about new green supply chain trends and technologies.

Final Words

- Green supply chain management involves integrating sustainable practices into the entire supply chain.

- Collaboration is essential, requiring engagement with internal teams, suppliers, and other stakeholders.

- Green supply chain companies should optimize logistics, invest in sustainable technologies, and partner with eco-friendly suppliers.

- Evaluating environmental impact metrics, obtaining sustainability certifications, assessing supplier practices, and conducting lifecycle assessments are crucial for gauging the effectiveness of green supply chain initiatives.

- Regular stakeholder engagement positions companies to meet current standards and future challenges.

Frequently Asked Questions

Q1: What is Green Supply Chain Management?

GSCM integrates eco-friendly processes across the product lifecycle to cut emissions, waste, and resource use while maintaining quality and compliance.

Q2: How is a green supply chain different from a sustainable one?

Green focuses on environmental impacts; sustainability adds social and economic pillars. GSCM is a core component of broader sustainability programmes.

Q3: What benefits can GSCM deliver?

Lower costs, reduced legal risk, stronger brand reputation, innovation, better supplier ties, improved risk management, and long-term financial gains.

Q4: What are key objectives of GSCM?

Reduce carbon footprint, deploy energy-efficient tech, minimise waste and recycle, source responsibly, manage lifecycle impacts, comply with regulations, and use resources efficiently.

Q5: How do we start transforming our supply chain?

Audit current impacts, set targets, engage stakeholders, redesign products, optimise logistics, adopt sustainable technologies, partner with certified suppliers, and track results.

Q6: Which supplier standards matter?

ISO 14001 is foundational. Depending on your sector, layer relevant energy, waste, or product-stewardship standards to ensure measurable performance.

Q7: How can logistics cut emissions?

Optimise routes, consolidate loads, use fuel-efficient vehicles, shift modes to rail/sea when viable, and improve backhauls to reduce fuel and emissions.

Q8: Why is lifecycle management important?

It embeds eco-design, better materials, reduced packaging, and end-of-life recovery, ensuring impacts are addressed from sourcing to disposal.

Q9: How does GSCM manage risk?

By proactively addressing resource scarcity, regulatory change, and environmental disruptions through diversified inputs and supplier resilience.

Q10: What metrics should we track?

Energy and emissions intensity, water use, waste and recycling rates, supplier compliance, transport modal splits, and progress versus targets.

Q11: How do we implement circular practices?

Design for durability and repair, run take-back and recycling, reuse materials, and align incentives with recovery rates.

Q12: What mistakes should we avoid?

Vague goals, single-issue focus, weak supplier engagement, poor data, and treating GSCM as a one-time effort rather than continuous improvement.