Value Chain Meaning

The concept of a value chain has been around since the 1980s when Michael Porter first introduced it in his book “Competitive Advantage”. A value chain describes a company as a series of processes or activities that improve a final product or service. Businesses can learn about the nature and purpose of each activity to identify areas where they might create a competitive advantage. Value Chain may be defined as, “A high-level model of how businesses receive raw materials as input, add value to the raw materials through various processes, and sell finished products to customers”. Porter’s Value Chain represents a system that explains how inputs are changed into outputs.

What is Value Chain Management?

Value chain management refers to the strategic process of maximizing value creation while minimizing costs in a company’s series of activities, from product conception to distribution and after-sales service. In essence, it involves optimizing the flow of products, services, and information from the producer to the customer. It is based on the understanding that the combined value of these activities will be greater if coordinated in a synergistic manner rather than treated as isolated operational elements. Effective value chain management contributes to a company’s competitive advantage, enhancing efficiency, increasing customer satisfaction, and ultimately, driving business growth.

What are the Benefits of Value Chain?

The significance of the value chain concept lies in its facilitation of a deeper understanding for companies about the variety of activities that contribute to value creation for their customers. Furthermore, this concept offers a pivotal structure for evaluating the relative costs and benefits of these diverse activities. Thus, companies are empowered to make informed decisions on how to refine their activities, thereby maximizing the value delivered to their customers. The benefits of implementing a value chain model in business operations are manifold:

1. EFFICIENCY IMPROVEMENT

A thorough understanding of the value chain enables businesses to identify inefficiencies within internal processes and take corrective measures, thereby improving operational efficiency.

2. COST REDUCTION

The value chain model aids in pinpointing areas where costs can be minimized without compromising on the quality of products or services.

3. COMPETITIVE ADVANTAGE

Through value chain analysis, businesses can differentiate their products or services, providing them with a competitive edge in the market.

4. CUSTOMER SATISFACTION

A streamlined value chain not only ensures top-notch product quality but also facilitates timely delivery, leading to enhanced customer satisfaction.

5. STRATEGIC DECISION MAKING

Value chain analysis provides valuable insights that assist in making strategic decisions, such as resource allocation and investment planning.

6. INNOVATION

By understanding the value chain, opportunities for innovation become apparent, fostering a culture of continuous improvement within the organization.

How Do Value Chains Work?

Value chains work by breaking down a business’s operations into strategically relevant activities. These activities are then analyzed to understand how they contribute to the creation of value in a product or service.

- The process begins with raw materials and input acquisition, followed by production, marketing, and finally, service delivery to the end consumer.

- Each of these stages in the value chain adds value to the final product or service, and by examining these stages individually, businesses can identify ways to optimize and enhance the overall value provided.

- This comprehensive understanding enables businesses to strengthen their competitive position by maximizing value creation and minimizing costs.

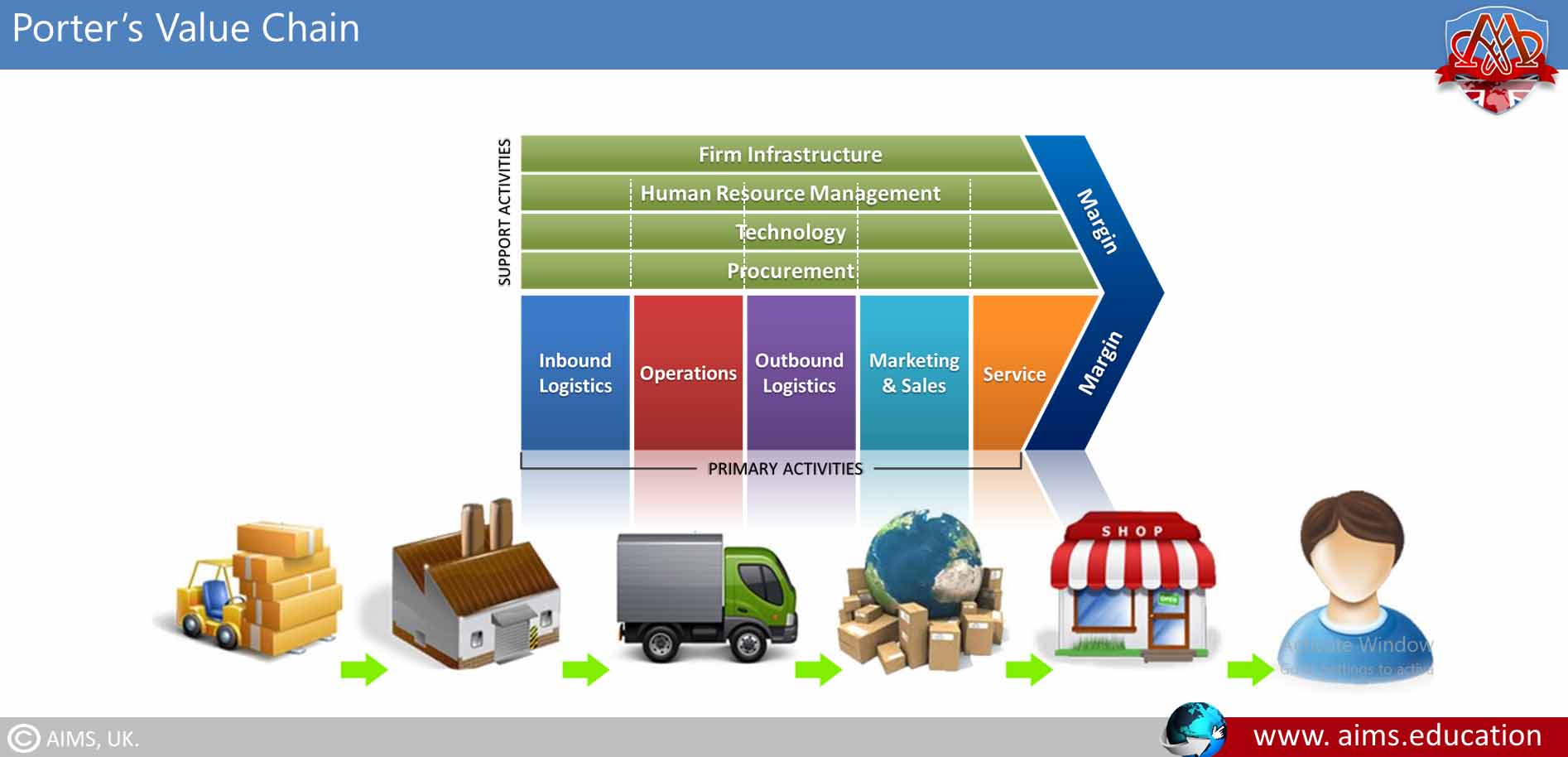

Porter’s Value Chain is a strategic tool used to analyze the activities through which a company can create value for its customers. The model breaks down the company’s operations into primary and support activities.

- Primary Activities: Direct involvement in producing and selling the product or service characterizes primary activities.

- Support Activities: Conversely, support activities function to enhance and enable the primary activities.

Primary Activities:

Primary activities are directly related to the creation, sale, maintenance, and support of a product or service. They consist of five steps: inbound logistics (receiving and warehousing of raw materials), operations (conversion of inputs into final product), outbound logistics (distribution of the product to the customer), marketing and sales (activities to enhance product attractiveness), and service (support to maintain the value of the product).

1. INBOUND LOGISTICS:

This part of the process actively involves all the necessary operations to accept and stockpile raw materials. Moreover, it establishes a decisive link with the reception, storage, and distribution of inputs.

2. OPERATIONS:

The operations phase takes raw materials and dynamically changes them into the final product, marking the activities that convert inputs into outputs. In this stage, operational systems are at play, actively creating value.

3. OUTBOUND LOGISTICS:

The outbound logistics embraces all the essential tasks to convey the accomplished product to the customer, comprising transportation, storage, and dissemination. These endeavors actively distribute your product or service to your customers.

4. MARKETING AND SALES:

It takes charge of sparking interest in the product and subsequently orchestrating its sale to consumers. Engaging in these processes aims to convince customers to choose your offerings over your competitors.

5. SERVICES:

Following the sale, services actively offer crucial support to clients, including customer service and technical guidance. These efforts are directly linked to the provision of after-sales service, ensuring continued customer satisfaction and loyalty.

Support Activities

Support activities, on the other hand, assist the primary activities in improving efficiency and effectiveness. They include infrastructure (organizational structure, control systems, company culture), human resource management (recruitment, training, development), technology development (technology to support value-creating activities), and procurement (purchasing input for value-creating activities).

By effectively managing these support activities, a company can enhance the efficiency and quality of its value chain, thereby creating superior value for customers and achieving a competitive advantage.

1. PROCUREMENT:

Procurement concerns the acquisition of resources necessary for the operation of the business. This extends beyond raw materials to include resources such as machinery, office supplies, and services.

2. TECHNOLOGY DEVELOPMENT:

This support activity involves the development and implementation of technologies that streamline operations, improve product quality, and provide a competitive edge. It spans a wide range of activities, from research and development to automation and software integration.

3. HUMAN RESOURCES MANAGEMENT:

It relates to the recruitment, training, development, and retention of employees, all of which are significant for maintaining a competent workforce that can effectively perform the primary activities.

4. INFRASTRUCTURE:

Infrastructure refers to the general systems and facilities that support the entire organization. It includes administrative tasks, planning and management, finance, quality control, and general services that help the organization to function effectively.

Examples of Value Chain

A value chain is a simple way to visualize how your business creates value for its customers. It shows the activities that take place from product development to distribution. When you first begin a business, it can be difficult to determine if your product is truly viable. Along the way, it’s important to learn how to identify and measure success. By understanding the value chain of your business, you can identify key metrics that can help you gauge how successful your product is.

When you start with the raw materials, you can see how those materials travel through the value chain until they reach your customers. The value chain starts with raw materials like wood, oil, and steel. Raw materials are then refined into products like oil and steel. These products are then shipped to stores or warehouses where they are sold to customers. When a company uses a value chain model, it can visualize how it creates value for its customers.

Example # 1: Value Chain of Toyota

At Toyota, the value chain comprises several well-coordinated activities that, collectively, have made the company a global leader in the automobile industry.

a. Inbound Logistics:

Toyota has a global network of over 200 suppliers, providing a vast array of parts and components. The company’s ‘Just-In-Time’ procurement and inventory management systems ensure that these components arrive exactly when they are needed, reducing inventory storage costs and improving efficiency.

b. Operations:

Toyota’s manufacturing process employs the ‘Toyota Production System’, a systematic approach to eliminating non-value-adding operations. This method, often referred to as ‘Lean Manufacturing’, emphasizes continual improvement, respect for people, and standard work practices.

c. Outbound Logistics:

Once the vehicles are produced, Toyota’s logistics network ensures that vehicles are safely delivered to dealerships across the globe. Their external distribution partners and internal systems work collaboratively to ensure efficient and timely delivery.

d. Marketing and Sales:

Toyota’s marketing strategies are effectively designed to appeal to specific market segments. They focus on the reliability, safety, and energy efficiency of their vehicles to attract and retain customers.

e. Service:

Toyota is known for its exceptional customer service, both during and after the sales process. It offers extended warranties, roadside assistance, and scheduled maintenance services. This focus on customer satisfaction not only encourages repeat business but also enhances Toyota’s reputation for dependability.

Through each stage of the value chain, Toyota demonstrates a strong commitment to creating value for its customers, enhancing its competitive advantage in the automobile industry.

Example # 2: Value Chain of Apple

Let’s take a look at another example: the value chain of Apple, a global leader in technology.

a. Inbound Logistics:

Apple’s inbound logistics involve sourcing high-quality components from various suppliers worldwide. These components include microchips, touch ID sensors, and more, which are crucial for the manufacturing of Apple products.

b. Operations:

The collected components are assembled into final products, such as iPhones, iPads, and MacBooks, at Apple’s manufacturing facilities. Apple invests heavily in R&D to ensure its products are innovative and user-friendly.

c. Outbound Logistics:

The finished products are then shipped to Apple stores and other retailers globally. Apple also sells its products online, delivering them directly to the customer’s doorstep.

d. Marketing and Sales:

Apple adopts a differentiated marketing strategy, focusing heavily on the unique design and advanced features of its products. It uses a mix of advertising, public relations, and direct marketing to reach its target audience. Apple stores, with their minimalist design and interactive product displays, also play a crucial role in selling the Apple experience.

e. Service:

Apple offers high-quality post-sales services, including technical support, software updates, and product warranties. Apple’s commitment to customer service strengthens its brand reputation and customer loyalty.

In conclusion, through effective value chain management, Apple continues to deliver innovative products and superior customer service, keeping it at the forefront of the technology sector.

What is Value Chain Analysis?

Value Chain Analysis is an analytical framework that assists in identifying business activities that can create value and competitive advantage for the organization. It involves examining all the activities that a business performs and understanding how they contribute to the value of the company’s products or services. Originally introduced by Michael Porter, the approach breaks down the company’s operations into strategically relevant activities to understand the behavior of costs and the existing and potential sources of differentiation. A thorough Value Chain Analysis can enable a company to isolate and optimize the processes that offer the highest value, thus helping to improve profitability and gain a competitive edge in the market.

How to conduct a value chain analysis?

Conducting a value chain analysis involves a series of well-defined steps:

1. Identify Activities:

Firstly, you must identify all the primary and support activities in your value chain.

- Primary activities are those directly involved in the creation or delivery of a product or service, like inbound logistics, operations, outbound logistics, marketing and sales, and service.

- Support activities, on the other hand, assist primary activities and include infrastructure, human resource management, technology development, and procurement.

2. Analyze Activities:

Analyze these activities to understand how they contribute to value creation. They include assessing the cost structure and identifying areas where you can reduce costs, improve operations, or enhance customer value.

3. Evaluate and Determine Differentiators:

Evaluate how each activity impacts your competitiveness, and identify the areas where you can differentiate yourself from competitors. It might be quality, cost, delivery speed, or any other factor that your customers value.

4. Identify Links:

Look for links between activities. Sometimes value can be increased by changing the way activities interact.

5. Formulate Strategy:

Based on your analysis, develop strategies to optimize value, reduce costs, and stake out a competitive advantage. This could involve strengthening weaknesses, exploiting opportunities, or mitigating threats within your value chain.

By consistently applying these steps, you can create a strong, competitive value chain that delivers value to your customers and achieves sustainable growth for your business.

Value Chain Mapping

It is a visual representation of all the activities involved in producing a product or service and delivering it to customers.

Value Chain VS Supply Chain:

In essence, the difference between a value chain and a supply chain lies in their scope and focus.

SUPPLY CHAIN for Flow of Goods:

- A supply chain is primarily concerned with the logistics of moving products from the point of origin to the point of consumption.

- It encompasses all the activities and processes involved in procuring raw materials, transforming them into finished products, and delivering these products to the end customers.

- It’s about managing the flow of goods, services, and information from suppliers to manufacturers to wholesalers to retailers to consumers.

VALUE CHAIN to Add Value:

- It delves deeper into the operations of a single organization. It scrutinizes every internal process that adds value to the product or service. It’s a tool for strategizing how to secure a competitive advantage by optimizing these value-adding activities.

- While a supply chain is a broad network of several companies working together, a value chain is a series of departmental interactions happening within a single company, from research and development to customer service.

- By examining the value chain, firms can identify areas of strength, discover opportunities for differentiation, and pinpoint areas where they can cut costs or increase efficiency.

What is the Role of Value Chain in Supply Chain?

The role of a value chain within a supply chain is critical and multifaceted.

- It primarily serves as a mechanism for understanding and optimizing the activities that create value within an organization, thereby enhancing the overall efficiency and effectiveness of the supply chain.

- The value chain provides a lens to scrutinize each step of the internal processes, from the initial conception of a product or service to its ultimate delivery to the customer. Such examination allows a company to identify potential efficiencies, reduce wastage, and enhance the customer’s perceived value.

Ultimately, a well-managed value chain can foster competitive advantage, not just within the organization but throughout the entire supply chain network.

What is a Value Stream?

A value stream, another important concept in the field of business operations, refers to the full sequence of activities undertaken by a company to deliver a product or service to the market. While not unlike a value chain in concept, a value stream focuses on visualizing the flow of processes, identifying bottlenecks or points of waste, and streamlining operations to improve overall efficiency. By examining a value stream, businesses can better understand the flow of value in their organization and work to enhance it, thereby bolstering both their operational efficacy and their competitive positioning.

Learning Opportunities for Enhanced Value Chain Management

To deepen one’s comprehension and improve the management of a value chain, obtaining formal education in this domain could prove to be extraordinarily valuable. For beginners, acquiring a certificate in logistics might serve as a stepping stone by imparting fundamental knowledge about the logistics components within a value chain. For those desiring convenience and accessibility, an online course in supply chain management and an online diploma in logistics and supply chain could be a suitable choice, providing insights into the procedures involved in efficiently managing a value chain. Aspiring leaders may find an MBA degree in supply chain management and a doctorate in supply chain and logistics beneficial, gearing them with strategic and managerial perspectives for effective value chain management.

Summary:

To conclude, the value chain plays an integral role in managing and optimizing the processes that create value within a business. Not only does it enhance the overall efficiency of the global supply chain, but it also allows a company to uncover potential efficiencies and increase customer satisfaction. Whether we look at it from a value chain or a value stream perspective, the ultimate goal remains the same: to identify and mitigate waste, streamline operations, and bolster competitive positioning. Embracing these concepts is critical for businesses aiming to retain their competitive edge in the increasingly complex and fast-paced world of today.