Global Supply Chain Definition & Meaning:

Global supply chain management (GSCM) is a strategic management process that involves managing the flow of materials, information, and people across multiple locations to produce items for global markets. According to the global supply chain definition, “The global supply chain focuses on the global business, and it applies to firms who are increasingly focused on both domestic and global markets”. Globalization is however defined as, “The interdependence of economies globally that results from the growing volume and variety of international transactions in goods, services, and capital, and also from the spread of new technology.” Globalization and supply chain management influence each other.

Importance of Global Supply Chain in Today’s Economy

Global supply chain management encompasses a broad range of activities that can take place at many different organizational levels. It has become an essential part of businesses around the world as they strive to become more competitive and meet customers’ needs in increasingly complex environments. While global supply chain management may be a relatively new concept for many organizations, it is an important part of every business’s strategy.

- By managing their supply chains effectively, companies can reduce costs, increase efficiency, and improve customer service. In addition, by collaborating with suppliers and other stakeholders across their supply chains, they can strengthen their relationships and build trust with their partners. Thus, global or international supply chain management is critical to the success of any business today.

- Pursuing a supply chain management specialization certification or a supply chain diploma can be a game-changer for professionals aiming to excel in the complex and dynamic world of global supply chain management.

How Did Globalization Shift to Supply Chains?

“The World Is Flat” author and journalist Tom Friedman explains why and how globalization has shifted into warp drive, pointing to supply chains as one of the factors making the world “flat.” What he means by “flat” is “connected” and how the lowering of trade and political barriers as well as the incredible technological advances of the digital revolution have made it possible to do business and communicate nearly instantaneously with millions around the globe. In this section, we’ll first look at the ways that this flattening impacts globally dispersed supply and demand.

- We’ll describe the players in cross-border trading, some of the rules and risks of the export-import game, free trade zones, and trading blocs.

- We’ll conclude our discussion with the operational considerations as well as the implications of being a respected global supply chain management participant who operates with integrity.

Understanding the Global Supply Chains:

There is a discussion surrounding globalization and its effects on business, and there is no doubt that supply chain competitors are increasingly going head to head on a worldwide playing field. Competing in supply networks that cross borders adds a set of problems when compared to doing business in one market where competitors play by the same rules, invoice and pay in the same currency, communicate in the same language and pay roughly the same rates for labor, supplies, and raw materials. It is also possible to overplay the novelty of the situation.

1. The History of Global Supply Chain Management:

Trade has been international roughly since the invention of the ocean-going vessel, if not since the onset of the camel caravan or the roaming of nomadic tribes. Moreover, there is more effort being made now to normalize cross-border trading than ever before, with international rule-making bodies and regional trade agreements. But the speed at which the game is played has increased exponentially in this age of the Internet, jets, and nearly instantaneous global connectivity. In the I700s, when the British shipped tea to their colonies, the product, and its carrier was out of touch for weeks while global supply chain management back home waited for news.

2. Technology and Global Supply Chain Software:

Now, with global positioning, barcoding, and satellite communications, every item on board every ship or plane can be tracked every minute of the day or night. Computer software coordinates transportation using multiple carriers and multiple modes. And computer optimization models crunch the numbers on all sorts of international variables to guide warehouse site selection. Automation, computerization, and electronic information technology all work together to keep tighter control on costs, reduce lead times, and make international supply chains an inevitable fact of competitive life.

3. Growing Importance of Globalization:

It is now possible to place manufacturing outside one’s home country if local costs and conditions indicate that such a move will be profitable. Assembly, of course, can be done many thousands of miles/kilometers and several borders away from the manufacture of components to fit the specifications of regional markets. Meanwhile, purchasing can compare the prices for source materials around the globe (taking into account all the costs involved in getting the materials and components from the source to the manufacturer). Goods can be shipped to warehouses anywhere using various combinations of vehicles owned and operated by transport specialists for whom the whole world is home.

All these things are possible. But that means that all these things are rapid – becoming necessary as well. What works for my competitor’s company becomes a necessity for mine. Additionally, there is a huge importance of supplier relationship management. To understand it, refer to our lecture, which is a complete guide to supplier relationship management (SRM)

4. Managing a Global Supply Chain:

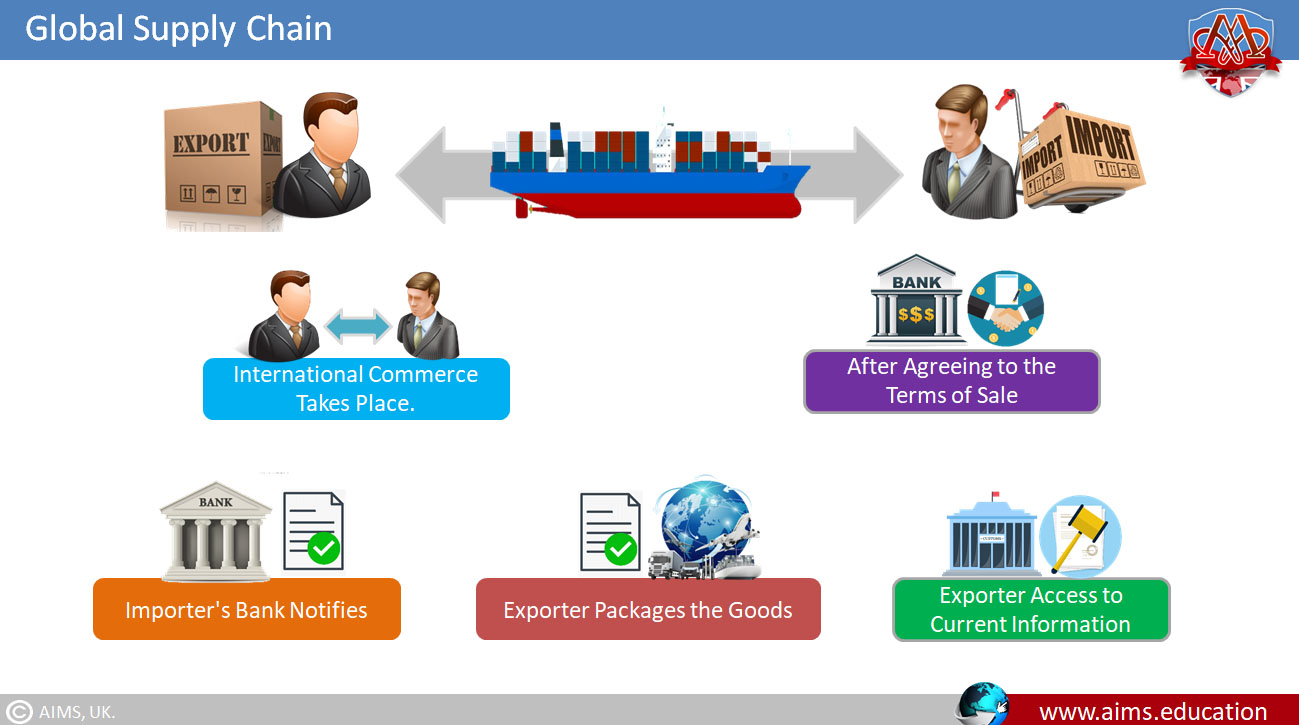

International commerce takes place between an exporter (the seller) and an importer (the buyer or customer). A number of intermediaries may perform one or more specialized services before the items sold in one country arrive at the customer’s dock in another. In the last module, we discussed the growing use of logistics specialists to carry out specific operations for a client firm (3PLs) or to coordinate the entire logistics function (4PLs). To understand it in more detail, refer to 3PL vs 4PL – what is a 4PL & How They Differ From 3PLs.

The use of specialized logistics intermediaries is even more common in the export-import business than in domestic supply chains. There are simply many more issues to contemplate when you send a product across borders into countries with different rules, different currencies, and different languages. And so it may be cost-effective for a company sending, or receiving, an international shipment to pay out considerable sums in fees or commissions to acquire these services.

How Does International Supply Chain Management Work?

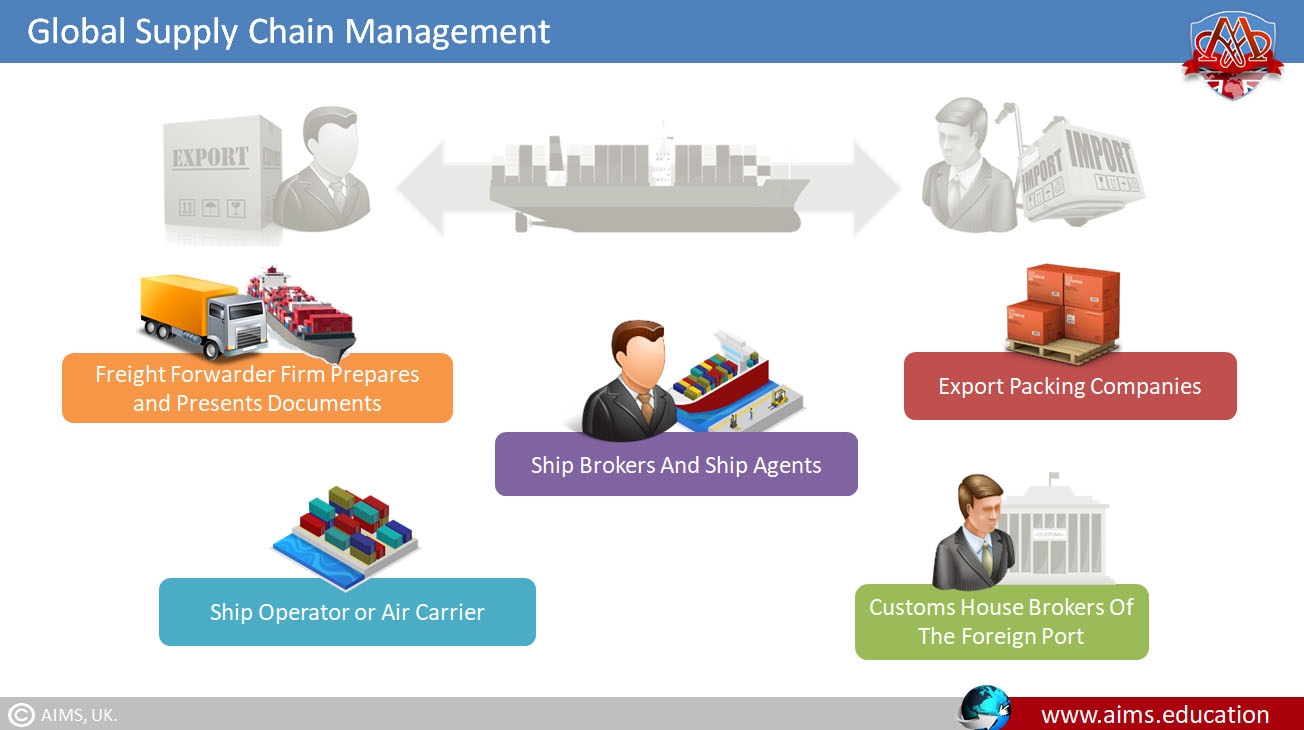

The following are some of the titles and job descriptions of the intermediaries who assist in getting cargo across borders and through customs in global supply chain management. You will explore the basic roles of the following:

- Freight forwarders.

- Non-vessel operating common carriers (NVOCCs).

- Consolidators.

- Customs house brokers.

- Export management companies (EMCs) and export trading companies (ETCs).

- Shipping associations.

- Shipbrokers and ship agents.

- Export packing companies.

1. Role of Freight Forwarders:

The freight forwarder, foreign freight forwarder, or just plain forwarder in a global supply management arranges transportation for commercial cargo. A freight forwarder is defined as “the ‘middle man between the carrier and the organization shipping the product, often combining] smaller shipments to take advantage of lower bulk costs.” A foreign freight forwarder is “an entity that picks up goods at the production site and coordinates transport to the foreign customer’s location.” Foreign freight forwarders are not themselves carriers, nor do they buy and resell space on carriers. They are, instead, independent agents, regulated in the United States by the Federal Maritime Commission.

2. Role of NVOCCs:

A common carrier is “transportation available to the public [that] does not provide special treatment to any one party and is regulated as to the rates charged, the liability assumed, and the service provided. [The common carrier] must have a certificate of public convenience and necessity from the (U.S.) Federal Trade Commission for interstate traffic.” In global supply chain management non-vessel operating common carriers (NVOCC) buy space on inland carriers and resell it to shippers at a marked-up price. NVOCCs handle only the part of the shipment traveling from a port to the importer’s dock or from an exporter’s dock to a port.

NVOCCs can be distinguished from forwarders in three ways:

- NVOCCs buy and resell space on carriers while forwarders do not.

- NVOCCs perform the physical work of consolidating, loading, and unloading cargo (using non-union labor to undercut the rates charged by carriers). Forwarders do not provide labor.

- NVOCCs can handle the freight in many cases, such as shipping by a motor freight carrier from Charlotte to Hawaii.

3. Responsibilities of Consolidators:

The consolidator, when dealing with global supply chain management, combines small shipments into larger ones to qualify for full vehicle discounts. Generally, this service is provided to fill containers for intermodal shipments, such as turnarounds carrying cargo between an inland warehouse and a port. Consolidators are distinct from NVOCCs, but they may work under them. A consolidator that is not affiliated with an NVOCC contracts with a forwarder or a carrier to arrange the transportation.

4. Responsibilities of Customs House Brokers:

In global supply chain management, customs house brokers assist importers by shepherding shipments through customs. In terms of the global supply chain, their job is to ensure that all documentation required to pass customs is complete and accurate. These days, the information required to clear customs passes through computer interfaces, such as the Automated Broker Interface System in the United States and the Pre-Arrival Review System (PARS) in Canada. Replacing paper shuffling with electronic data transfer has shaved considerable time off the process of getting cargo through customs. The customs house broker pays all import duties under a power of attorney from the importer. Liability for any unpaid duties lies with the importer, not the broker.

5. Roles of Export Management Companies (EMCs):

When companies want to expand from domestic to foreign markets, they may turn for assistance to foreign trade specialists in either export management companies (EMCs) or export trading companies (ETCs) rather than adding internal expertise. While there may be some overlap in the types of services offered by EMCs and ETCs, there is a distinct line between their approaches. The EMC is generally not an exporter itself but rather a consultant to the exporters that hire it. The ETC, on the other hand, is itself an exporter rather than a consultant to an exporter.

REASON FOR HIRING:

A common reason to hire an EMC is to acquire representation in a particular market where the EMC has special knowledge and connections. By working with an EMC, the exporter gains access to current information about the preferences of consumers in that market and about local customs and government regulations. Knowledge of local conditions enables an EMC to help the exporter avoid offending consumers or officials by inadvertent misinterpretations of the culture or the politics of the importer’s country. Finally, EMCs often cultivate friendly relationships with host governments, and this can help ease the exporter’s goods through customs.

6. Role of Export Trading Companies (ETCs):

An ETC, by contrast in a global supply chain management, looks for companies making goods that it wants to buy and resell in a foreign market. Its functions, therefore, may include any or all of the following:

- Locating importers to buy the goods.

- Overseeing export arrangements.

- Preparing and presenting documentation.

- Arranging transportation overseas and inland.

- Complying with regulations.

7. Role of Shipping Associations:

Smaller exporters band together in shipping associations to qualify for the rate discounts that carriers offer to larger shippers. Before deregulation ocean liners were required to publish their rates. Smaller shippers, seeing the rate schedules, could ask for similar deals. Since deregulation, carriers and larger shippers have been able to sign confidential rate agreements. In response, smaller shippers have formed shipping associations—usually nonprofit organizations—to negotiate with carriers on the same terms as larger shipping firms.

8. Responsibilities of Ship Brokers and Ship Agents:

Shipbrokers and ship agents assist exporters with the details of arranging ocean transport.

- A ship broker is an independent operator that brings exporters together with ship operators who have appropriate vessels available to carry the shipper’s freight. With detailed knowledge of carrier schedules, the broker can help the exporter find a ship that will be in port when its cargo is ready to travel.

- A ship agent works for the carrier rather than being an independent contractor. When a ship is headed for port, the shipping agent arranges for its arrival, berthing, and clearance; while the ship is in port, the agent coordinates unloading, loading, and fee payment. Shippers contact ship agents for information about the arrival and availability of ships.

9. Role of Export Packing Companies:

Export packing companies provide the specialized packaging services required for cargo that may have to undergo long journeys and pass customs inspections in another country. Hiring a specialist in export packaging provides three advantages for a shipper:

- By choosing the most appropriate materials, the packager in global supply chain management can expedite the movement of cargo through customs.

- Specialized packaging can help exports survive the rough handling and adverse climate changes that can occur when cargo travels long distances. The packing company can choose packaging materials that provide adequate protection with the least bulk and weight.

- In some countries, import duties are based on the weight of the cargo including the packaging, not just the weight of the goods.