What is Supply Chain Framework?

The supply chain is considered a series of interrelated processes, where each process encompasses any activity that adds value to a product or service. There are 3 main types of supply chain management frameworks, and each supply chain framework has a set of different supply chain management processes. The Supply Chain Framework is defined as a “Guiding structure outlining principles, strategies, and components of a supply chain”. You can design different supply chains using each framework, as each supplier management framework offers different benefits, focus areas, and applications – and its selection depends on the product or service being produced and delivered.

Listed below are the three widely used supply chain management frameworks, and learning one approach will help you understand the others:

- GSCF (Global Supply Chain Forum) Framework.

- APQC (American Productivity & Quality Center) Process Classification Framework.

- SCOR (Supply Chain Operations Reference) Model.

Objectives of Supply Chain Management Frameworks

There are two main objectives of a supply chain management frameworks: Value Addition and Interdependence.

- Value Addition represents the activities that enhance a product or service’s appeal to customers.

- Interdependence represents other processes such as ordering components, manufacturing, sales, and delivery. Each of them rely on one another.

Types of Supply Chain Management Frameworks

Supply chain management processes may differ across supply chain industries, however, different supply chain management frameworks exist to aid in designing and measuring supply chain performance. There are a lot of similarities between these three supply chain frameworks. Let us take a review of each:

1. GSCF Framework

The GSCF supplier management framework was developed by researchers at Ohio State University. The GSCF supply chain framework highlights the following eight essential supply chain processes:

- Customer Relationship Management.

- Supplier Relationship Management.

- Customer Service Management.

- Demand Management.

- Order Fulfillment.

- Manufacturing Flow Management.

- Product Development and Commercialization, and,

- Returns Management.

Focus Areas of GSCF

The GSCF supply chain framework is mainly focused on the following 3 areas:

- Transaction management between companies.

- Importance of customer and supplier relationships.

- Product development as a crucial process.

2. APQC Process Classification Framework

The APQC has established a comprehensive supply chain framework in which the processes are categorized into the following 13 areas:

- Develop Vision and Strategy.

- Develop and Manage Products and Services.

- Market and Sell Products and Services.

- Manage Supply Chain for Physical Products.

- Deliver Services.

- Manage Customer Service.

- Develop and Manage Human Capital.

- Manage Information Technology (IT).

- Manage Financial Resources.

- Acquire, Construct, and Manage Assets.

- Manage Supply Chain Risk, Compliance, Remediation, and Resiliency.

- Manage External Relationships, and,

- Develop and Manage Business Capabilities.

Structure of the APQC Framework

Each of the above-mentioned categories in the APQC framework consists of process groups, and each process group contains several activities and tasks.

3. SCOR Supply Chain Framework

The SCOR or Supply Chain Operations Reference Model is one of the widely used supply chain management frameworks that map supply chain into six top-level supply chain processes. These processes are:

- Plan,

- Source,

- Make,

- Deliver,

- Return, and,

- Enable.

Key Characteristics of Supply Chain Management Processes in SCOR

- Plan: This process connects with all other processes to align the supply chain activities.

- Source, Make, and Deliver: These processes describe the logical flow from sourcing materials to delivering products to the customers.

- Return: This supply chain process integrates feedback loops for product returns.

- Enable: The final process focuses on necessary capabilities and technologies that support supply chain operations.

Evolution in the SCOR Model

Initially developed by PRTM, the SCOR Model has transitioned through various iterations, with version 12. In this version, the latest SCOR Digital Standard is available.

Benefits of Supply Chain Management Frameworks

Following are the three key benefits of the supply chain management frameworks:

- Identifying trade-offs.

- Ensure that decisions align with business goals.

- Focus on critical metrics for effective supply chain management.

Applications of Supply Chain Management Frameworks

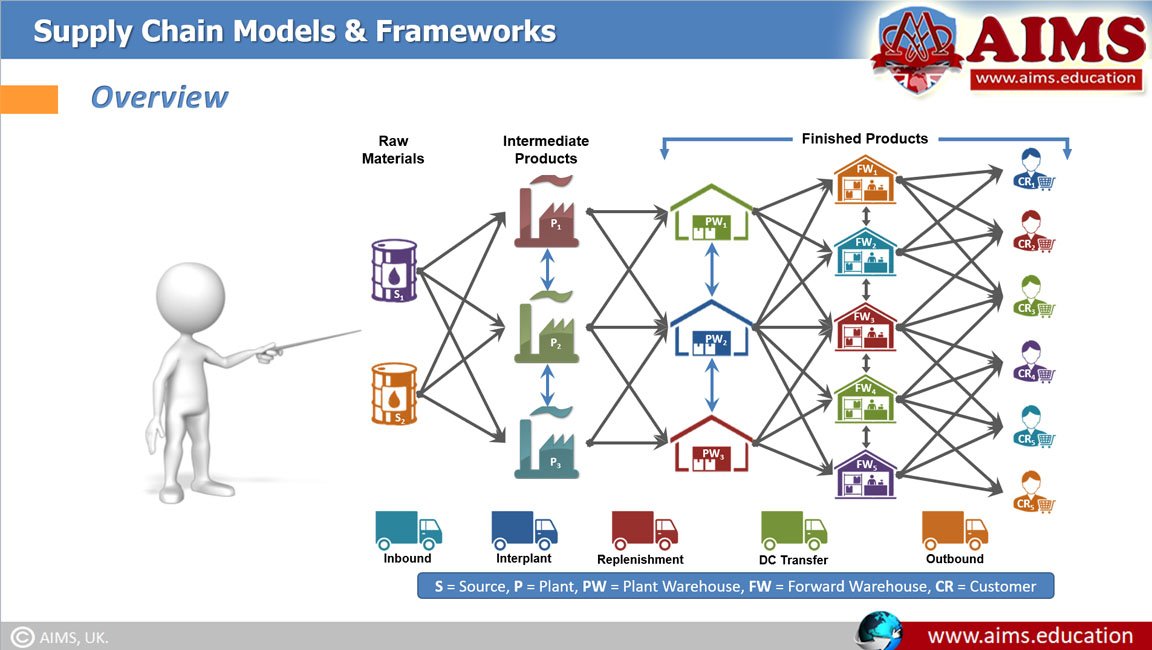

Supply chains can often belong to multiple categories. Each type of company may need to design different supply chains, and each requires a different supply chain framework that may align with their strategy. Here are some different categories of supply chains and each may require a different supply chain framework:

1. Manufacturing

In the manufacturing model, the components and raw materials are delivered to the factories.

2. Business-to-Business (B2B)

In B2B supply chains, companies are the primary customers. This supply chain is also referred to as industrial supply chain.

3. Business-to-Consumer (B2C)

It considers that individual consumers are the customers. This type of supply chain is also called a “retail supply chain”.

4. Consumer Packaged Goods (CPG)

CPG supply chains involve frequently purchased items or consumer goods, such as food and cosmetics.

5. E-commerce Supply Chain

The e-commerce supply chain facilitates online ordering and delivery of products and services, to the customers.

6. White Goods Supply Chain

White goods refer to large appliances. They may include refrigerators and stoves, which require special handling and installation by trained technicians, transportation, and staff for the management of logistics.

7. Agricultural Supply Chain

This supply chain is related to the handling of grains, fruits, vegetables, herbicides, fertilizers, and livestock. It is also called the agricultural supply chain model, and it often depends on seasonal variations.

8. Cold Chain

Cold supply chains are specifically designed for perishable items like food and medicine. In cold chains, refrigeration must be maintained throughout the supply chain process.

9. Hazardous Materials (HazMat)

The hazardous supply chain or HazMat Model addresses the unique handling requirements. These materials may include flammable, explosive, corrosive, or radioactive products, and they necessarily require special licenses and permits.

10. Medicine and Medical Equipment

The Medicine and Medical Equipment supply chains require strict adherence to storage protocols, expiration monitoring, and regulatory compliance.

11. Maintenance, Repair, and Overhaul (MRO)

MRO supply chains are focused on delivering the service parts and tools for equipment maintenance and repair.

12. Government Supply Chain

These supply chains are often bureaucratic and slow. The government supply chains manage large quantities of materials. They adhere to rigid processes with strict penalties in case of any errors.

13. Military Supply Chains

Military supply chains deliver military-related equipment and weapons over long distances on short notice. Military supply chains may utilize both military and civilian resources.

14. Humanitarian Logistics and Disaster Response

The humanitarian logistics and disaster response supply chains are established post-emergency to deliver food, medicine, and other necessary items to affected individuals.

15. Project Supply Chain

Project supply chains are related to temporary endeavors like construction. They consist of multiple vendors, who are capable of fulfilling limited orders within a short timeframe.

16. Reverse

The reverse supply chain is responsible for the return of products from customers back to suppliers.

Supply Chain Framework Examples

Recognizing the distinctions among these supply chains is essential for you to choose the specific supply chain framework for the best results. Given below examples list the above-mentioned categories of supply chains, and analyzes the preferred supply chain framework for each supply chain category:

| Supply Chain Framework | Supply Chain Category | Why this Supply Chain Framework Could be the Best Choice? |

| GSCF Framework | Manufacturing Supply Chain | GSCF framework emphasizes relationships and strategic planning, which is crucial factors in production and manufacturing. |

| APQC Framework | Business-to-Business (B2B) | APQC’s process classification helps streamline and standardize processes. |

| SCOR Model | Business-to-Consumer (B2C) | SCOR focuses on supply chain optimization and customer satisfaction, ideal for retail supply chains. |

| SCOR & GSCF Framework | Consumer Packaged Goods (CPG) | Both frameworks support collaboration with suppliers and retailers. |

| SCOR Model | E-commerce Supply Chain | SCOR model’s focus on process management and scalability suits the rapid order shifts in e-commerce. |

| APQC Framework | White Goods Supply Chain | APQC facilitates process improvements, so it helps manage complex logistics and installation of white goods. |

| GSCF Framework | Agricultural | GSCF’s coordination-focused framework may benefit agricultural supply chains better. |

| SCOR Model | Cold Chain | SCOR’s efficiency can help maintain product quality throughout cold supply chains. |

| GSCF Framework | Hazardous Materials (HazMat) | GSCF’s strategic relations are essential for handling regulatory requirements, which are frequently needed in these supply chains. |

| SCOR Model | Medicine and Medical Equipment | For medicine, SCOR ensures efficiency and compliance, which are extremely important in the medical industry. |

| APQC Framework | Maintenance, Repair, and Overhaul (MRO) | APQC can aid better when standardized service parts management is needed. |

| GSCF Framework | Government Supply Chain | GSCF’s focus is on strong governance, which may be a better choice. |

| SCOR Model | Military Supply Chains | SCOR’s adaptability and process optimization are effective for the dynamic needs of military logistics. |

| GSCF Framework | Humanitarian Logistics and Disaster Response | GSCF provides coordination strategies, which are most important in case of disaster. |

| APQC Framework | Project Supply Chain | APQC’s structured methodology can better manage project-based, short-term supply chains. |

| SCOR Model | Reverse | SCOR is suited for reverse logistics, which pays attention to efficiency and logistics cost reduction. |

What are SIPOC Attributes?

Identifying SIPOC (Suppliers, Inputs, Process, Outputs, Customers) attributes helps in analyzing supply chain processes. Here is a short review of the SIPOC processes:

- Suppliers: Provide necessary inputs.

- Inputs: Include raw materials and data.

- Process: The main activity being analyzed in the supply chains.

- Outputs: Products, services, and information produced in the supply chains.

- Customers: End-users of the outputs.

SIPOC Example

Let us understand SIPOC with the help of the picking process:

- Suppliers: Receiving department and inventory systems.

- Inputs: Inventory items and pick instructions.

- Process: Steps taken to pick up the Order.

- Outputs: Items picked and related documentation updates.

- Customers: The shipping department is responsible for delivering the product to the customer.

The SIPOC structured approach aids automating the supply chain processes while considering the impact on suppliers as well as the customers.