Role of Supply Chain Metrics in Supply Chain Performance

“What gets measured gets done” highlights the importance of assessing supply chain performance to enhance overall business outcomes. First of all, you should define your supply chain performance objectives and identify the appropriate metrics for measuring your supply chains. Supply Chain metrics serve as reference points to monitor the effectiveness of people, processes, and technology in your supply chain. You can improve your supply chain performance by capturing and disseminating supply chain metrics among your teams, customers, and suppliers. Clear communication of defined metrics is important for driving performance and achieving your business goals.

Setting Supply Chain Performance Goals

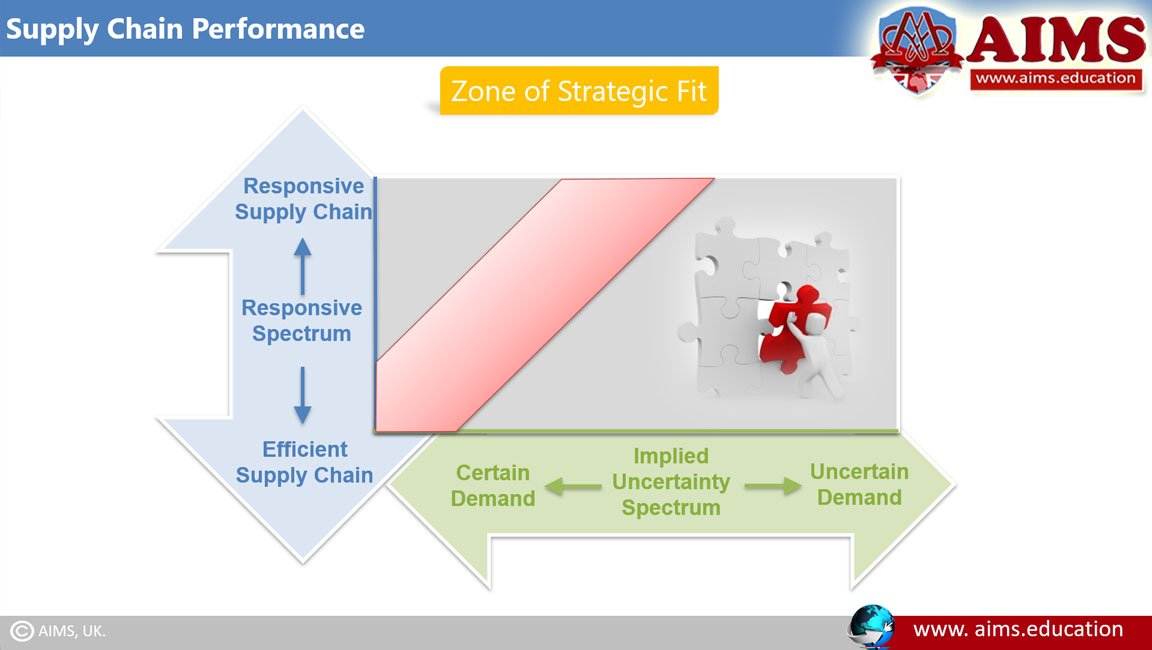

Supply chain performance goals often involve trade-offs related to asset utilization. Companies must balance efficient use of money with value creation and profit generation.

5 Key Considerations for Supply Chain Performance

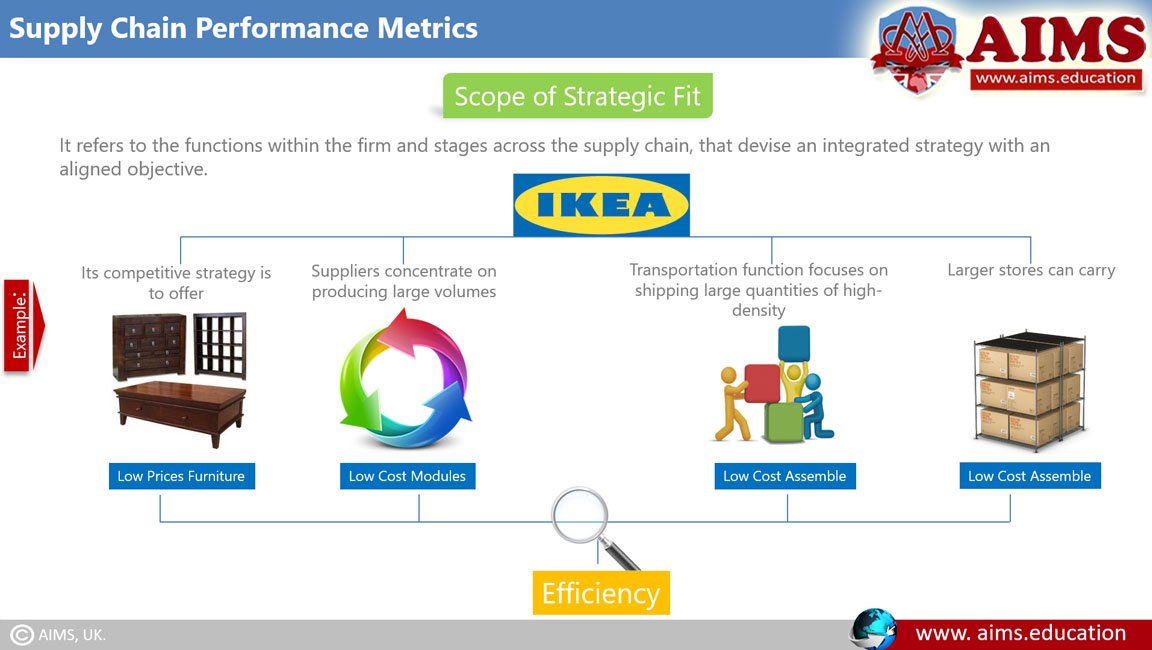

1. Alignment with the Business Plan

Supply chain performance goals should be derived from the company’s business plan.

For Example:

- Growth Focus: If the company is focus on goals, then the goals should emphasize availability and customer service.

- Cost-Cutting Focus: When cost-cutting is the main goal, the goals may target inventory reductions, capacity utilization, and supplier price reductions.

Aligning supply chain metrics with the business plan helps demonstrate the value of supply chain management.

2. Aligning Supply Chain Metrics with Customers

a. Team Effort

Successful supply chain management necessitates supply chain relationship and collaboration among partners to meet customer expectations at competitive prices.

b. Customer Metrics

To align metrics effectively, companies should inquire about their customers’ performance measures for suppliers. Adopting the external supply chain metrics can shift focus from internal matrices (such as capacity utilization) to customer-centric metrics (such as on-time delivery).

c. Comprehend Customer Supply Chain Metrics

Comprehending customer supply chain metrics is vital, as definitions may vary. For instance, delivery supply chain performance management may be assessed based on shipping or arrival times, affecting how companies manage their supply chain operations.

3. Sharing Supply Chain Metrics with Suppliers

a. Transparency and Collaboration

Suppliers must understand how their supply chain performance is evaluated. Sharing scorecards and metrics can foster supply chain collaboration aimed at mutual benefits.

b. Sustainability Considerations

If customers prioritize sustainability in their purchasing decisions, suppliers should be encouraged to report their sustainability metrics. Collaborating on sustainability initiatives can lead to improvements across the entire supply chain.

4. Inventory Management

It is important to note that low inventory may lead to stockouts and wasted capacity. On the other hand, high inventory can unnecessarily tie up working capital. So, you should set performance goals for inventory that address these conflicts.

5. Selecting Metrics Wisely

Companies must be strategic in choosing what and how to measure to improve supply chain performance and manage trade-offs effectively.

Types of Supply Chain Metrics

Supply chain matrices can be classified into two types:

1. Quantitative Metrics

Quantitative supply chain matrices are objective measures, such as units produced or revenue generated. Many systems track quantitative supply chain metrics automatically (e.g., warehouse and transportation management systems).

2. Qualitative Metrics

Qualitative supply chain matrices are subjective and based on perceptions, such as customer satisfaction. They may not be easily quantifiable but are critical for understanding supply chain performance.

Examples of Types of Supply Chain Management Metrics

Suppose a Food Restaurant is using the following three supply chain key performance indicators:

- Order-to-Delivery Cycle Time: This quantitative metric measures the time from order placement to food delivery.

- Perfect Order Proficiency: This metric tracks the percentage of orders delivered accurately and on time. It is also a quantitative matric.

- Net Promoter Score: Gauges customer satisfaction and willingness to recommend. It is a qualitative metric.

We may conclude that a balanced approach involving both the quantitative and qualitative supply chain management metrics provides comprehensive insights into supply chain performance management, highlights areas for improvement, and creates value in supply chains.

Transforming Qualitative into Quantitative Metrics

Qualitative metrics can be adapted into a quantitative format using scoring systems (for example, by rating customer satisfaction on a scale of 1 to 10). Despite the numerical output, the metric remains subjective.

Perception of Metrics

Quantitative supply chain management metrics are often seen as superior due to their objectivity. However, qualitative metrics can be equally valuable.

Internal vs. External Supply Chain Metrics

- Internal Metrics: These metrics measure factors that are important to the company (e.g., inventory turns).

- External Metrics: These metrics assess factors that are significant to customers and suppliers (e.g., perfect order fulfillment).

Leading VS Lagging Supply Chain Metrics

- Leading Metrics: Leading metrics are the indicators of future supply chain performance measurement (e.g., current customer orders predict future deliveries).

- Lagging Metrics: Lagging metrics reflect past performance (e.g., last month’s fuel expenses).

Aligning customer-facing supply chain management metrics with customer measurements is important for minimizing discrepancies in your supply chains.

How to Identify Performance Attributes?

Before defining useful metrics, one must identify the specific attributes of the supply chain to measure. This process can be complex due to the interconnectivity of supply chain management processes. For example:

A Factory is implementing a lean supply chain. In this case, the company should ensure that:

- Inventory Focus: The parts should arrive no more than one day in advance.

- Transportation Focus: They should maximize freight capacity on each truck.

In this case, conflicting supply chain goals between inventory and transportation metrics require a combined metric approach to foster collaboration.

How to View the Performance of Supply Chain Metrics?

For simultaneous assessment of multiple metrics, dashboards can be utilized to provide a comprehensive view of supply chain measurement.

17 Key Supply Chain Metrics

Listed are the 17 key supply chain performance metrics

Asset Management Efficiency Metrics

It is one of the key supply chain metrics, and it includes the following:

1. Cash-to-Cash Cycle Time

This metric indicates the say between purchasing inventory and collecting accounts receivable.

2. Return on Supply Chain Fixed Assets

This metric indicates the financial return from supply chain infrastructure.

3. Return on Working Capital

It measures the efficiency of end-to-end supply chain operations.

Optimizing Operational Metrics

4. Supplier Metrics

Key supplier metrics to be considered to improve the supply chain performance include the following:

- Number of suppliers,

- On-time shipping and receipt and,

- Product quality (e.g., parts per million with defects).

5. Procure-to-Pay Metrics

This metric accesses the duration of the procure-to-pay cycle, and it reveals insights into sourcing efficiency.

6. Purchase Price Variance (PPV)

PPV is a supply chain performance metric that compares standard costs against actual costs to assess procurement effectiveness.

7. Customer Service Metrics

Metrics such as order fill rate, on-time shipment, and product returns gauge supply chain performance from the customer’s perspective.

8. Capacity, Throughput, and Yield Metrics

- Capacity: Potential processing capability.

- Throughput: Actual material processed over time.

This lecture is part of an executive diploma in supply chain and logistics management and an online certificate in supply chain management program. The AIMS Institute of Supply Chain Management designed and offers these career-oriented programs for professionals seeking knowledge, skills, and growth in the supply chain management industry.

Financial Supply Chain Metrics

9. Financial Statements

Key documents included in this supply chain matric are:

- Balance Sheets: Snapshot of assets and liabilities.

- Income Statements: Overview of profitability over a period.

- Cash Flow Statements: Timing of cash inflows and outflows.

10. Accounts Payable Metrics

Monitoring accounts payable provides insight into supplier relationships and potential cash flow issues. Resolution of these issues ultimately impact positively on the performance.

11. Total Spend Metrics

Tracking spending trends helps you identify the performance issues, and you are able to separate direct and indirect costs for clearer analysis.

12. Savings Metrics

Demonstrating cost savings from supply chain improvements is important to justify future investments.

Perfecting People Metrics

13. Engagement Metrics

Employee satisfaction is measured qualitatively through surveys, while quantitative metrics (e.g., complaints filed) offer additional insights.

14. Productivity and Efficiency Metrics

You may directly measure the productivity of many employees. For Example:

- Number of customer service calls handled by the customer services representative.

- Number of suppliers handled by the procurement department.

- Performance of technical staff by considering the manufacturing output rates.

15. Turnover Metrics

Tracking employee turnover may easily give you insights into the job satisfaction level and associated costs of keeping them.

16. Safety Metrics

Safety supply chain performance metrics are important to maintain a healthy work environment. Examples of lagging safety matrices include the following:

- The lost-time incident rate is how many times someone gets injured badly.

- Days passed without any injury.

- Total cost of claims filed.

17. Waste Metrics

Monitoring carbon emissions in green supply chain management and landfill contributions allows your company to address the environmental impacts of your supply chain and align with customer and regulatory expectations.

Summary

By understanding and implementing the 17 Key supply chain metrics mentioned above, your organization can enhance performance, improve efficiency, and support sustainable supply chain management practices.

Frequently Asked Questions

Q1: What are supply chain metrics?

Supply chain metrics are performance indicators that track efficiency, cost, quality, and customer satisfaction within the supply chain process.

Q2: Why are supply chain metrics important?

They help organisations monitor operations, identify inefficiencies, and align supply chain performance with overall business goals.

Q3: What are the 17 key supply chain metrics?

They include metrics on cash-to-cash cycle time, working capital, supplier performance, procure-to-pay cycle, PPV, customer service, throughput, and sustainability.

Q4: What is the difference between qualitative and quantitative metrics?

Quantitative metrics are numeric and measurable, such as delivery time, while qualitative metrics assess perceptions like customer satisfaction or engagement.

Q5: How can companies align supply chain metrics with business goals?

Companies should derive metrics from their business plans—focusing on cost reduction, customer service, or sustainability depending on strategic priorities.

Q6: What are internal and external supply chain metrics?

Internal metrics track company-focused performance, such as inventory turns, while external metrics measure supplier or customer satisfaction.

Q7: What is the role of suppliers in performance metrics?

Suppliers should share scorecards and collaborate on sustainability and quality metrics to strengthen transparency and supply chain performance.

Q8: How do leading and lagging metrics differ?

Leading metrics predict future outcomes like incoming orders, while lagging metrics analyse past performance such as previous delivery times.

Q9: What are financial supply chain metrics?

They include metrics such as accounts payable, cash flow, and cost savings, helping assess financial health and efficiency of the supply chain.

Q10: How do safety and waste metrics support sustainability?

Tracking workplace safety incidents and carbon emissions helps build a responsible, sustainable supply chain aligned with global standards.