What is Supply Chain Planning?

Before engineering and managing a supply chain, it is essential to write your objectives and plan your supply chain accordingly. An effective supply chain planning process provides you with an opportunity to evaluate alternatives and make informed decisions. By doing so, your supply chain can make the best use of resources and maximize your business outputs. It is important to know that the supply chain planning system is not a singular event; rather, it is an ongoing, iterative process that involves several supply chain planning steps, which enables the supply chain to adapt the evolving business conditions, improve business efficiency, and reduce your supply chain costs.

How to Balance Supply & Demand in Supply Chain Planning Process?

The central question in supply chain planning is: “How are we going to balance supply with demand?” This involves the following three main approaches:

- Make-to-stock,

- Make-to-order, and,

- Engineer-to-order

1. Make-to-Stock Approach

This approach relies on forecasting customer demand. This is how it works:

- Products are manufactured and ready before receiving customer orders.

- Often referred to as a push system since products are pushed toward customers without confirmed orders.

For Example: Buying a car from a dealership involves purchasing from pre-manufactured stock based on demand forecasts.

2. Make-to-Order Approach

Using this supply chain planning approach, the manufacturing and distribution services wait for customer orders. Using this approach:

- Products are not made or moved until an order is received.

- This system is a pull system, where customer orders pull products through the supply chain.

For Example: If a customer desires a specific car configuration not available in stock, the dealership orders it from the factory, illustrating a make-to-order process.

3. Engineer-to-Order Approach

In this approach, customized products are created based on specific customer requirements. In this system:

- The product design cannot be completed until the customer provides specifications.

- Similar to make-to-order, it operates as a pull system, with engineering and manufacturing triggered by customer orders.

For Example: A unique request, such as modifying a car for specific customer needs (e.g., creating a kennel compartment), requires custom design and sourcing, exemplifying the engineer-to-order approach.

Although the finished products may appear similar to customers, the underlying supply chain processes differ significantly. Aligning these processes is essential for effective supply chain planning.

6 Key Supply Chain Planning Steps

Step 1: Plan Your Resources

The supply chain planning process is fundamentally structured around specific goals or requirements. The various elements utilized to make a supply chain functional are collectively referred to as resources. These resources are:

- People: Human resources are crucial for supply chain management operations.

- Facilities: Locations where operations occur.

- Machines: Equipment necessary for production.

- Inventory: Goods that are stored for future use.

Every resource within the supply chain has constraints, which are limitations that affect its capacity. These constraints can be categorized into two main types:

- Physical Limitations: These include operational restrictions of resources.

- Imposed Limits: These are constraints set by financial, safety, and policy regulations.

Some of these common supply chain constraints are:

- Work Hours: Employees can only work 40 hours per week without incurring overtime costs.

- Maintenance: Machines require servicing after every 1,000 hours of operation.

- Certification: Operators must be certified to use specific equipment.

- Storage Conditions: Finished goods inventory cannot be stored outside during winter.

Identifying and managing constraints is important in supply chain planning process. A plan that overlooks constraints can lead to missed financial targets and operational inefficiencies. For instance:

- A plan that assumes a 45-hour workweek without considering overtime costs could lead to budget overruns.

- A strategy that includes outdoor inventory storage in winter could be impractical and lead to losses.

In this step, the supply chain plan outlines how to meet requirements while considering available resources and their constraints. Here is an example of this supply chain planning step:

Requirement: Produce 100 widgets per day.

Resources Needed:

- Manufacturing equipment capable of producing 10 widgets per hour.

- Raw materials with a five-week delivery timeframe.

- Skilled employees available only on Tuesdays.

So, your supply chain plan must articulate how to effectively utilize these resources to meet the production requirement, taking all supply chain constraints into account. An effective supply chain planning process is contingent upon a clear understanding of both the resources available and the constraints that limit their use. Comprehensive research and judgment are essential to ensure that the supply chain planning process is viable and capable of achieving its objectives.

Step 2: Analyze Your Customers

The next supply chain planning step is to find and align the customer needs. Each customer has specific needs, and understanding these needs is crucial for delivering the expected value for your business. We have already discussed the models that are used to identify customer needs. They are:

- Engineer-to-Order Supply Chain.

- Make-to-Order Supply Chain.

- Make-to-Stock Supply Chain.

There are three primary methods that are used to analyze customer needs:

1. Market Segmentation

This method groups customers based on demographic characteristics. For individuals, it considers factors like location, income, and age. For businesses, the considered factors are industry classification, annual revenue, and the number of employees. This market segmentation ensures that the supply chain planning process is aligned with segment needs.

2. Persona Development

This method creates profiles of imaginary customers that represent real customer characteristics. For example, a person named James, worked 60 hours a week, and he values convenience in laundry products. The outcomes of this method help you identify the customer values, informing supply chain improvements.

3. Key Customer Analysis

This method helps you identify customers most likely to purchase products. The factors that you consider are understanding the customer needs, purchase behaviors, and price sensitivity.

Using Customer Relationship Management (CRM) Systems

Using CRM systems provides data on customer interactions and purchases. They assist in creating personas, analyzing market segments, and enabling the tracking of key customer behaviors.

By leveraging these systems and tools, businesses can enhance their supply chain planning process to better meet customer expectations and deliver value effectively.

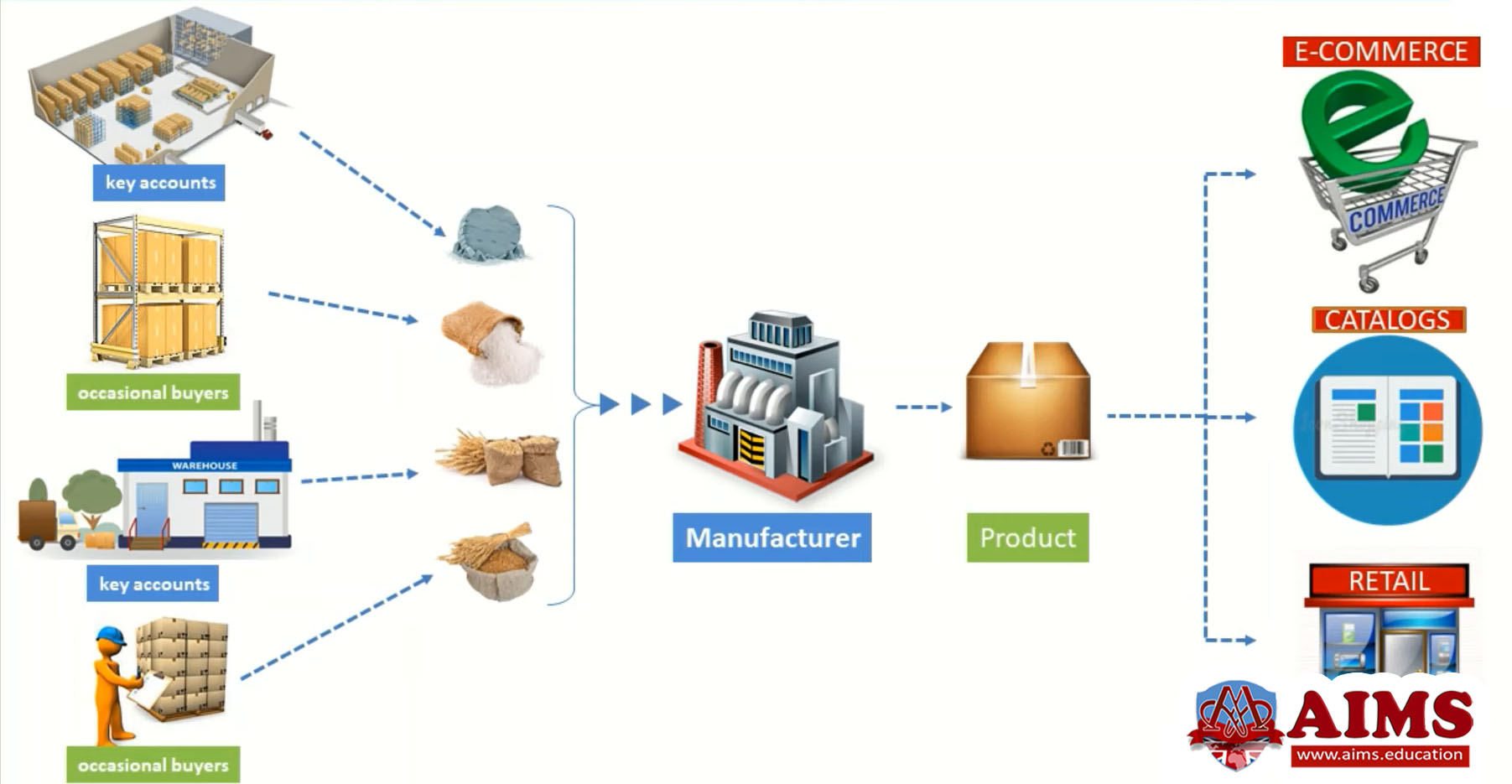

Step 3: Prepare a Product Plan

This supply chain planning step is influenced by both demand-related factors, such as customer feedback, and supply-related factors, such as supplier quality issues. There are several factors that influence supply chain changes. They are divided into two types:

- Demand-Related Factors: Customer feedback can lead to adjustments in the supply chain.

- Supply-Related Factors: Issues like supplier quality problems may necessitate changes in the supply chain.

When you are aware of the resources, you may better understand the availability, sourcing, and cost of materials are crucial for design decisions. Product characteristics often evolve and must be integrated into the supply chain planning process.

Let us see the examples of how the product characteristics affect the supply chain:

- In the Automotive Industry, automakers switch between metals based on current prices, which affects product design and planning.

- In the food industry, seasonings differ by location, necessitating tailored supply chains despite uniform branding elements.

The supply chain planning process is dynamic, requiring ongoing adjustments based on material availability, cost fluctuations, and product characteristics. Understanding these factors is vital for an effective supply planning process and resource allocation.

Step 4: Plan Your Production

Your production plan is essential to your supply chain planning process, and it determines the timing, location, and methods for producing products while adhering to production constraints. It involves managing different types of inventory, such as:

- Raw Materials Inventory: Materials received from suppliers before production begins.

- Work-in-Process (WIP) Inventory: Partially assembled products between manufacturing steps.

- Finished Goods Inventory: Completed products ready for sale.

The production plan ensures product availability while respecting production constraints. In case the production is centralized, all raw materials are shipped to a single facility. This enhances the efficiency of your supply chain planning, especially when large capital investments are involved.

However, it may result in longer delivery times and higher transportation costs.

Step 5: Planning Your Logistics

Getting products to customers involves a complex delivery system, which is termed logistics. This process includes the movement and storage of products, facilitated by a logistics (or distribution) network. Logistics networks may be divided into two types:

- E-commerce Fulfillment: For companies that sell small products online, with a distribution center near the factory, streamlines shipping.

- Large-scale Distribution: When companies sell through big-box stores. In this case, the products are shipped in larger quantities, requiring different logistics resources.

Your supply planning process for this phase depends on the type of company so that you may choose a logistics network accordingly. Efficient logistics planning not only enhances customer satisfaction but also promotes sustainability and cost-effectiveness in logistics management.

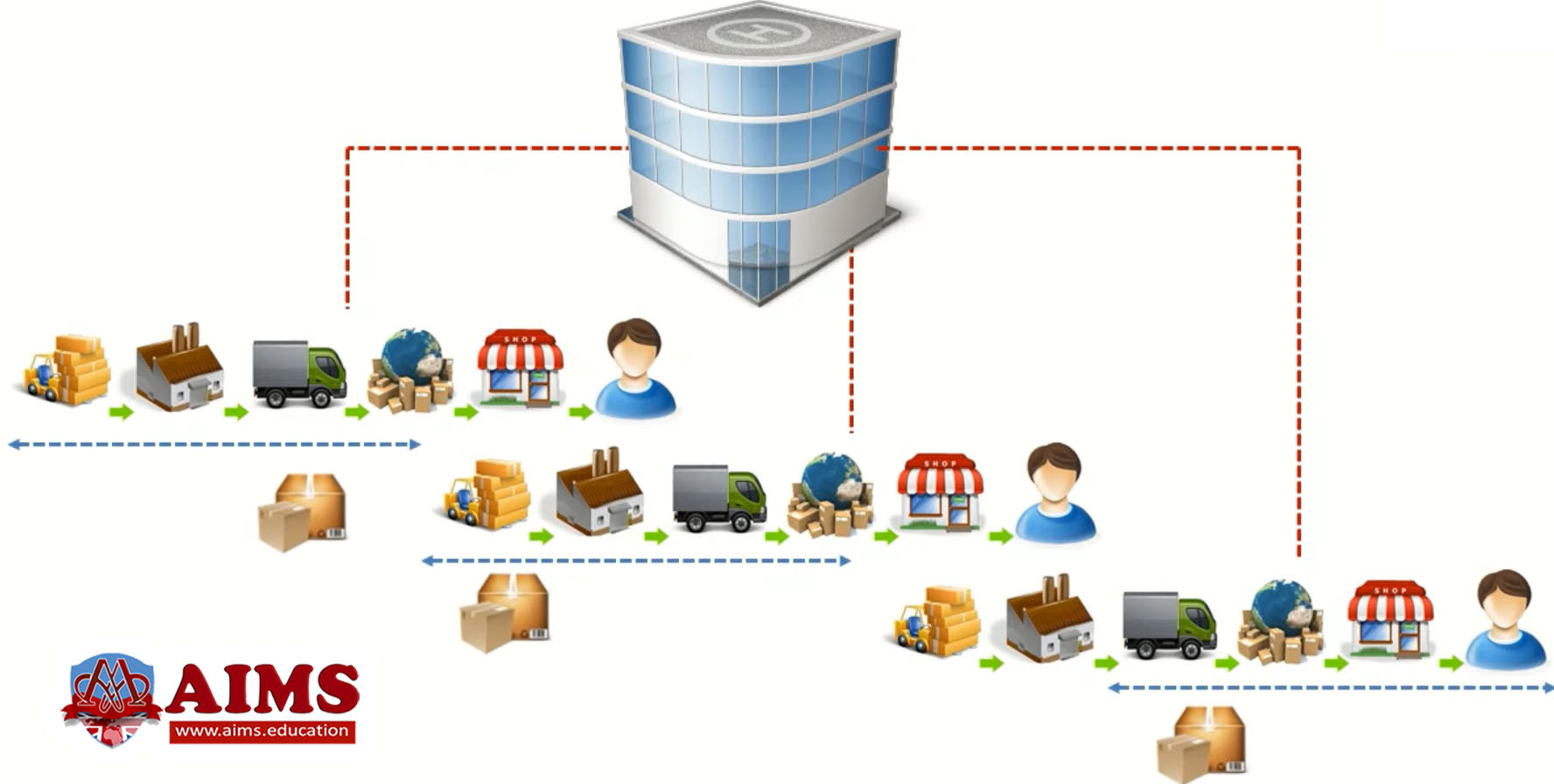

Step 6: Plan Your Reverse Supply Chain or Logistics

The reverse supply chain is defined as a “Network facilitating the return of products from customers to the company.” It involves more than just returning unwanted products; and it can include repairs, remanufacturing, recycling, and safe disposal of hazardous materials. Returns must be an integral part of the supply chain planning process and often neglected. Typical return rates range from 5 to 10% across industries and can be as high as 30% in e-commerce. The following are the goals of this planning step:

- Minimize Costs: Streamline processes to reduce logistics costs and expenses.

- Maximize Value: Focus on recovering money from returned products.

Companies often provide easy return processes to encourage future sales. In some cases, for example, returned defective computers can be refurbished and resold, recovering significant value rather than being written off.

A well-structured reverse logistics network can create value by enhancing customer satisfaction and minimizing losses from disposed products. The supply chain planning strategies that you may adopt at this stage could be recycling and/or remanufacturing:

- Recycling: Many products, like electronics, contain recoverable materials (e.g., precious metals).

- Remanufacturing: Used components (cores) can be processed into like-new parts, offering cost savings to customers.

The development of closed-loop supply chains allows companies to ensure all products can be recycled effectively.

Benefits of a Supply Chain Planning Process

Supply chain planning helps your company create a supply chain that ultimately benefits all the partners. The following are the key benefits of supply chain planning:

- Optimization of resource allocation to ensure optimal use of available resources;

- Increased predictability of supply chain operations;

- Reduced inventory levels and other costs, which ultimately save money;

- Lesser risk of disruptions and increased efficiency;

- Improved customer satisfaction;

- Planning and optimizing the supply chain within an organization can help you improve productivity, increase customer satisfaction, and lower costs. In return, successful supply chain planning steps will result in a more resilient organization that is better equipped to compete with fierce global competition;

- When implemented correctly, a supply chain plan can help you reduce uncertainty and complexity, which will help you improve the predictability and control of processes along the supply chain management; and;

- It can also help you minimize supply chain risks and reduce costs while achieving faster growth and expansion.

Why Do You Need a Supply Chain Plan?

During the planning stage of the supply chain, organizations need to monitor the status of each step in the process. To do this, you need to know:

- What your suppliers are doing?

- What the performance of your inventory is? and

- How long it will take for the product to reach the customer?

A supply chain plan should include all this information and more. It should be planned in a way that show you the current state of the operation, forecast when problems may occur, and let you know how to solve situation with the right tools and resources.

Students of AIMS’ MBA with Logistics and Supply Chain Management program learn to plan and implement supply chains using the supply chain planning steps. The master’s program may also lead to PhD – Supply Chain Management and Logistics.

How to Plan a Supply Chain?

The modern supply chain is a magical combination of technology and business processes that allows companies to efficiently source, produce, and deliver goods to customers. When everything is working as it should, the supply chain makes sense of raw materials, manufacturers, distributors, stores, and consumers. It manages all of these inputs through different stages and movements until they reach the customer. With such complexity comes a challenge for supply chain professionals who have to plan the entire process accurately and in a way that minimizes risks while maximizing potential.

Types of Supply Chain Planning Systems

So, what are the key supply chain planning systems that you can use to make your processes more efficient and effective? There are two main key systems that we believe are the most important ones in what concerns supply chain planning systems:

1. Training and Motivating Employees

Supervisors need to be furnished with the right knowledge and tools to run successful planning. This is the only way they can then make sure that the employees have the right tools to succeed. When the supervisor knows what is happening in real-time and knows how he should act in case of a disruption, he will be able to pass on the information to his employees, ensuring that the process is still in place.

2. Understanding the Future Demand

While this is easier said than done, there are different methods that you can use to ensure that you can reduce inventory, minimize waste, and improve in-shelf availability. One of the best strategies to implement this is by taking advantage of the forecasting methodology.

Frequently Asked Questions

Q1: What is supply chain planning?

It’s the set of processes that align demand and supply—demand planning, inventory, production, and S&OP/IBP—to achieve service, cost, and cash goals.

Q2: What are the key steps in the planning process?

Data prep, demand planning, inventory policy, supply and capacity planning, scenario analysis, S&OP/IBP consensus, execution, and continuous monitoring.

Q3: What do MRP, DRP, and APS systems do?

MRP plans materials; DRP plans finished-goods replenishment; APS suites optimise end-to-end with constraints and scenario modelling.

Q4: How does S&OP/IBP improve outcomes?

It reconciles demand, supply, and finance monthly so leaders can set capacity, inventory, and service trade-offs with clear accountability.

Q5: What data is essential?

Accurate BOMs, routings, lead times, historical demand, constraints, inventory parameters, service targets, and cost data.

Q6: Which KPIs should we track?

Forecast accuracy and bias, OTIF, inventory turns/DOH, capacity utilisation, plan adherence, stockouts/backorders, and total landed cost.

Q7: Common mistakes to avoid?

Poor data hygiene, single-number forecasting, ignoring constraints, static policies, siloed decisions, and skipping scenarios or reviews.

Q8: How do planning horizons differ?

Strategic (12–36 months) sets capacity/network; tactical (3–12 months) balances via S&OP; operational (daily–12 weeks) drives scheduling and replenishment.

Q9: How should planning integrate with ERP?

Sync master data and transactions with ERP/MES/WMS/TMS, enable near-real-time feeds, and govern approvals and hand-offs.

Q10: When should we upgrade planning software?

When replanning is slow, constraints can’t be modelled, scenarios are manual, data is stale, or growth needs multi-echelon analytics.

Q11: What benefits can effective planning deliver?

Higher OTIF, fewer stockouts, lower inventory and expedites, better utilisation, and faster, clearer decision-making.