What is Supply Chain Technology?

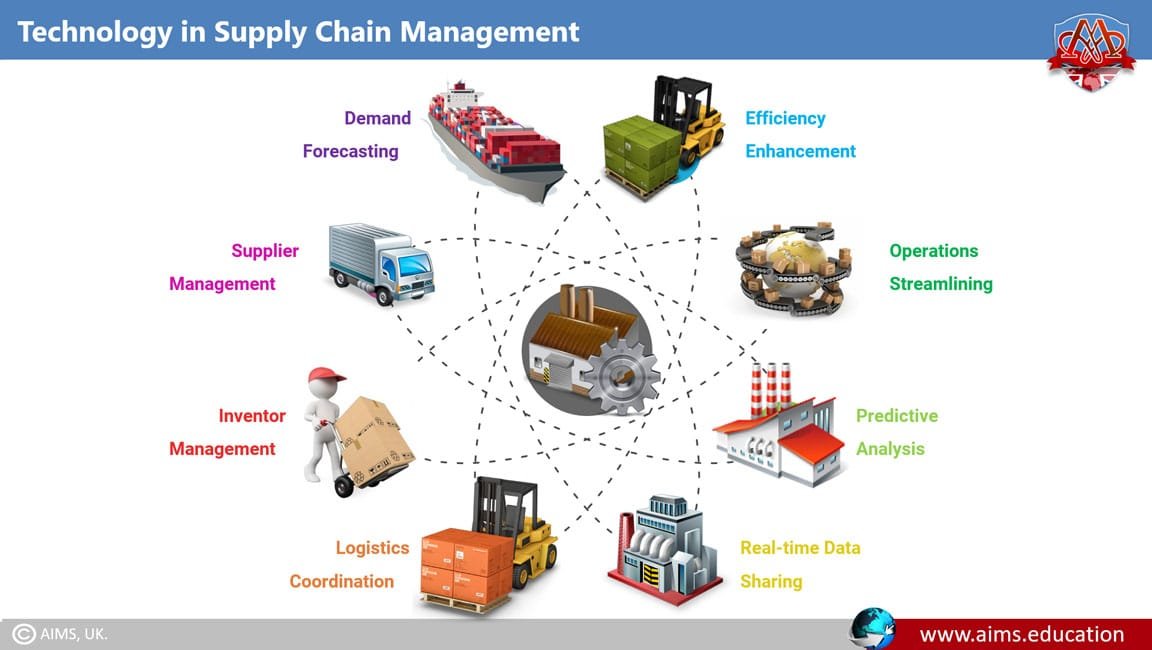

Technology is tremendous in reshaping the supply chain strategies in the business world by enhancing efficiency, streamlining operations, predictive analysis, and sharing real-time data. Technology is not considered a luxury these days but a prerequisite for businesses and industries to be a part of this competitive world. Supply chain technology is now an essential means of coordinating logistics, inventory management, suppliers, and demand forecasting. The transformation of a traditional to a digital supply chain is a fundamental shift in businesses, allowing them to manage their operations efficiently in minimum response time. For example:

- By implementing supply chain and logistics technology, companies can accomplish exceptional proficiency and flexibility levels and reduce fraud.

- Technology in supply chain management boosts digital infrastructure that permits firms to become accustomed to fast changes in market situations and continuously drive enhancement through their supply chain management.

How Technology Shapes the Supply Chain Management?

Supply chain management prospers in logistics, revolution, and supply chain analytics because of the introduction of new technologies. Supply chain technology has some distinct effects on the overall management of logistics and other related areas. Such as:

1. Enhanced Supply Chain Communication

Supply chain and logistics technology enhances efficient and satisfactory communication in supply chain management. It links all aspects of the supply chain and creates a solid production flow. This strong connection among supervisors and workers, and transparency in manufacturing from warehouse to delivery ensures high productivity.

2. Greater Efficiency in Supply Chain Processes

Implementing the supply chain management technology offers better performance, secure information, simplified operations, and improved efficiency. Integrating systems improves collaboration, problem identification, quick decisions, and solutions to keep operations smooth and speedy. Their instant responses save resources and time, leading to greater outcomes.

3. Beyond Transparency in Supply Chain Horizon

Supply chain technology trends offer suitable and consistent operation handling and transparency while delivering products according to the company’s needs. It offers an easy approach to update transparency and permits supervisors and employees to intercept when compulsory to safeguard the finished product.

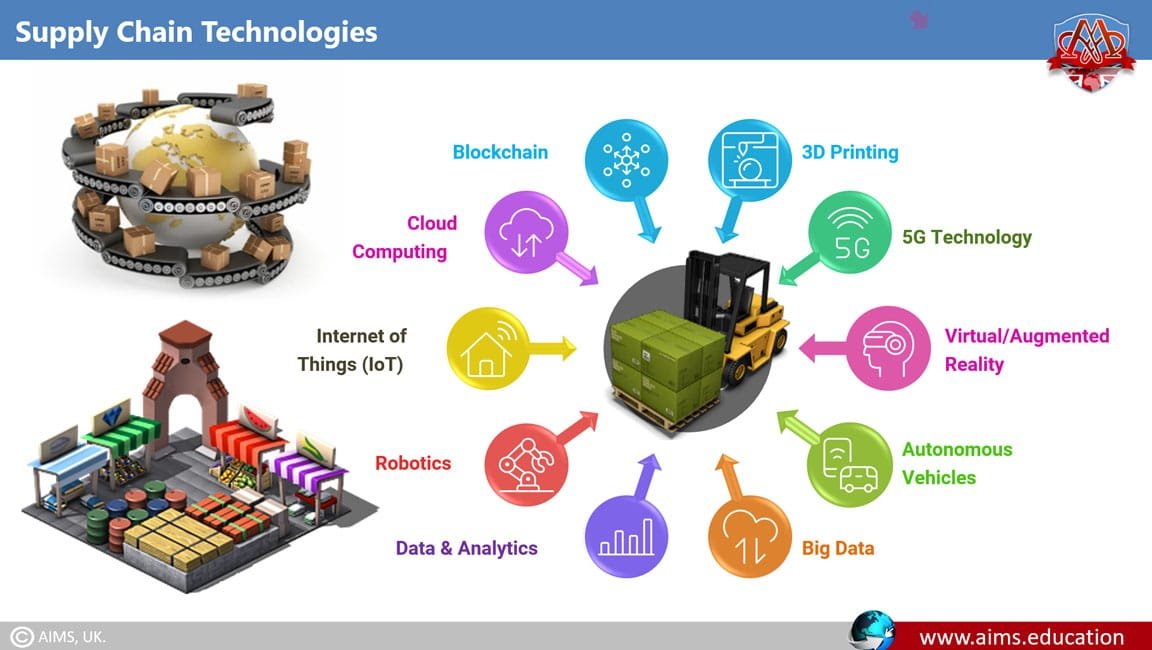

Top 10 Supply Chain Technology Trends

Several key technologies that enable real-time coordination, flexibility, and responsiveness across different supply chain management frameworks and functions make concurrent supply chains possible. Supply chain technology is a vast domain discussed in programs offered by AIMS, including the logistics management and supply chain diploma and MBA degree in supply and logistics management for skills and career growth. Let us review the main supply chain and logistics technologies, that are used in different ways:

1. 3D Printing in Supply Chain

3D printing supply chain technology or additive manufacturing is a shortened supply chain that minimizes supply chain management risk, increases speed to market, and lowers global impact by limiting the global shipping of goods. It permits supply chain businesses to develop prototypes and products on demand in minimum time at reduced cost.

2. 5G Technology in Supply Chain

The 5G technology offers quick, reliable connections for better collaboration and communication throughout the supply chain management. Nowadays, in the supply chain, smart devices such as 5G-enabled IoT sensors ensure the collection and analysis of supply chain related data in real time. During traveling, a manager can even track the exact location of the products and other factors like temperature and environment in real time.

3. Supply Chain Technology: Virtual/Augmented Reality

Virtual and augmented technology in supply chain management offers visualization and simulation in supply chain operations, enhancing decision-making and minimizing errors. Augmented technology enables employees to inspect specifications (including size and color) in the absence of physical products, therefore saving organizations storage space and money on undesirable products.

4. Using Autonomous Vehicles in Supply Chain

Autonomous vehicles such as drones and self-driving trucks provide improved delivery time at low cost by minimizing human errors and predetermined routes. This supply chain technology solution plays a major role in global supply chain processes.

5. Big Data in Supply Chain Technology

Big data offers proficient insight, decision-making, and process automation by analyzing raw data. Various data analytics techniques and processes have been automated into mechanical processes and algorithms that work on raw data for human consumption. Nowadays, however, organizations have introduced new supply chain technology to assist with procurement, supply chain risk management, and S&OP in supply chain management.

6. Data & Analytics in Supply Chain

Supply chain technology data and analytics offer great insight into supply chain processes and help organizations to overcome inefficiencies and understand how to make improvements.

7. Robotics Technology in Supply Chain

In supply chain technology, robotics has revolutionized the field of supply chain management. It provides automation of manual and recurring tasks and makes it easier for employees to concentrate on more strategies that increase their productivity. Robotics enhance accuracy and speed up processes, specifically in manufacturing and warehousing. Recently, robots have been able to overcome labor problems and act as last-mile workers in the future. The ways robots revolutionize manufacturing industries:

a. Delivery Robots

Delivery robots minimize the labor cost and remove the need for humans in hazardous places, minimizing safety and health costs.

b. Automated Trucking

Self-driving vehicles ensure the safe transport of goods and services without interruption to humans.

c. Sorters

Robots using artificial intelligence identify many products and classify them accordingly, eliminating tedious and laborious tasks for humans.

d. Automated Storage and Retrieval

It is a robot-assisted system that moves materials required for storage or retrieval according to consumer demand.

8. Internet of Things (IoT) in Supply Chain

Supply chain technology IoT consists of billions of sensors embedded in many devices within the supply chain. It allows data transfer within and between systems and controls actions during the supply chain process. Today, it is used for allocating materials, equipment services, and productivity monitoring.

IoT promotes risk because it uses the internet to control organizational processes and opens a way to cybersecurity dangers, but comparatively, it boosts manufacturing processes by detecting patterns and highlighting problems, providing insights about areas of improvement. This is crucial and valuable supply chain and logistics technology for anyone who wants to implement cutting-edge technology.

9. Role Cloud Computing for Supply Chains

Cloud technology for supply chain management offers computing services for large data processing and accessibility in organizations. It includes tools, processes, and infrastructure that provide people with an overview of the transportation of goods from anywhere. All the data on the cloud is always available and backed up against loss, theft, or damage. Most of the cloud configurations used in the supply chain management industry are:

a. Software-as-a-Service (SaaS)

It is hosted and distributed by third-party providers. At the same time, the customers approach it without developing any infrastructure. It updates and maintains automatically in the background.

b. Infrastructure-as-a-Service (IaaS)

IaaS is a tool that logistics and supply chain companies use to implement data analysis and cloud-based data management technologies. It consists of virtual machines, IoT sensors, networking technology, and energy-management infrastructure.

c. Platform-as-a-Service (PaaS)

It is important when app developers require a stable cloud-based development atmosphere where they test cloud services and particularly work on cross-compatibility with current goods and application programming interfaces (APIs).

10. Blockchain Technology in Supply Chain

Blockchain supply chain management meaningfully modifies how retailers and consumer-packaged-goods manufacturers execute their supply chains. The requirement of secure transactions and sustainability are motivating buyers to connect with brands. Blockchain offers these requirements by assuring the attribution of goods, a secure database for supply chain transactions, real-time tracking of products, and minimizing the risk of errors and fraud.

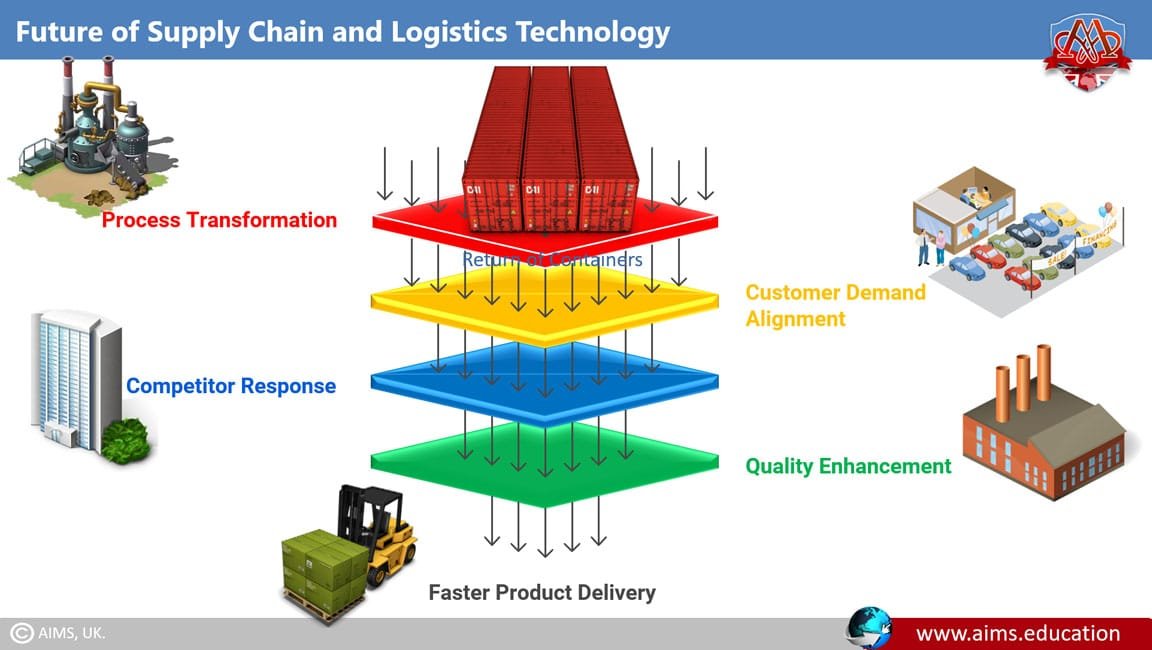

The Future of Supply Chain Technology

As the future of manufacturing is emerging gradually, supply chain and logistics technology is being directed to adopt better approaches to stay ahead in the dynamic market. It transforms the manufacturing process to meet customer demands and growing competitors. It makes industries deliver high-quality products quicker by highlighting their capabilities and analyzing the areas of improvement.

Frequently Asked Questions

Q1: What is supply chain technology?

It covers tools like IoT, robotics, AI/analytics, cloud, blockchain, AR/VR, and 5G that enhance planning, execution, visibility, and decisions across the end-to-end supply chain.

Q2: How does technology reshape supply chain management?

It connects stakeholders, automates routine tasks, enables real-time data sharing, and accelerates decisions—boosting efficiency, collaboration, and resilience.

Q3: What are the top supply chain technology trends?

3D printing, 5G, AR/VR, autonomous vehicles and drones, big data and analytics, robotics, IoT, cloud computing (SaaS/IaaS/PaaS), and blockchain.

Q4: How is 3D printing used in supply chains?

It enables rapid prototyping and localized production, reducing lead times, transport, and inventory while lowering costs and risk.

Q5: What does 5G enable in logistics and operations?

Low-latency, reliable connectivity for dense IoT, real-time tracking of location and condition, better collaboration, and faster response across fleets and facilities.

Q6: How do AR and VR improve performance?

They support visualization, digital work instructions, and simulation to reduce errors, storage needs, and rework while improving training and planning.

Q7: Where do autonomous vehicles add value?

In predictable routes and last-mile delivery, cutting labour costs and errors while improving safety and speed.

Q8: What is the role of big data and analytics?

They power demand forecasts, inventory optimization, risk detection, and S&OP; models automate decisions and reveal inefficiencies.

Q9: How does IoT help—and what are the risks?

Sensors provide live visibility and faster interventions; cybersecurity exposure is a key risk that must be managed.

Q10: What cloud models support supply chain systems?

SaaS for ready apps, IaaS for compute and data pipelines, and PaaS for building and integrating supply chain applications.

Q11: Why is blockchain relevant to supply chains?

It offers tamper-evident provenance, secure transactions, and real-time traceability—reducing fraud and improving compliance.

Q12: What does the future look like?

More autonomy, AI-driven planning, digital twins, and tighter partner data integration to deliver speed, quality, and resilience.