What is Supply Chain Management Software?

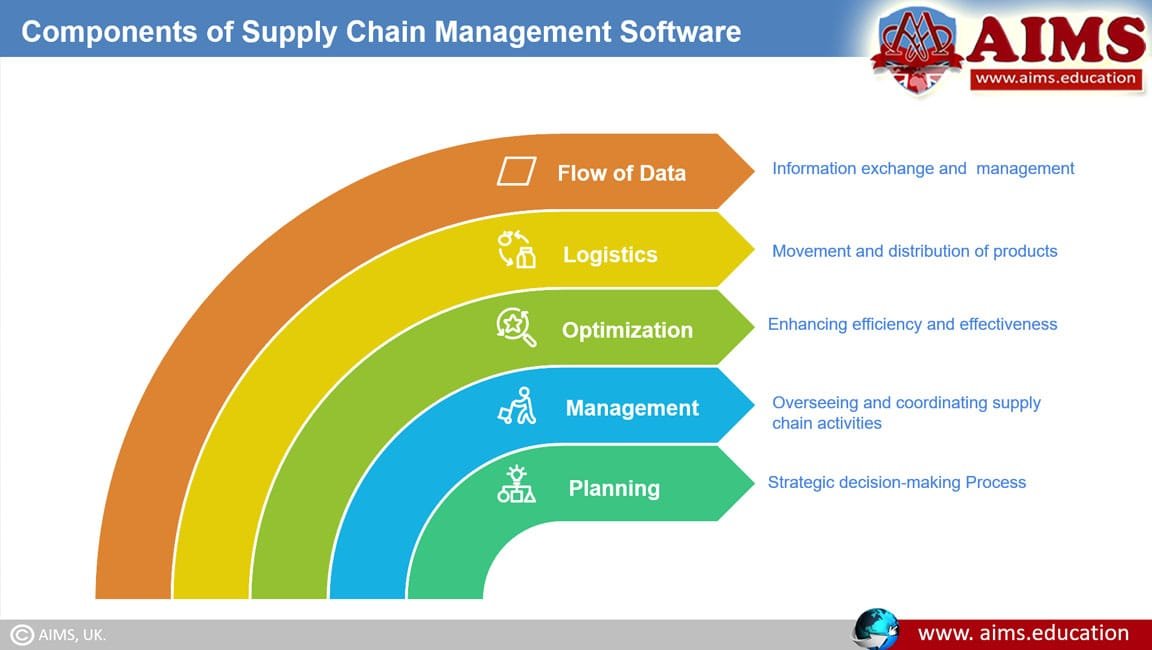

Supply Chain Management software is defined as “A suite of digital tools that helps companies plan, manage, and optimize their flow of goods, data, and finances across their supply chain.” Supply chain software facilitates tasks like inventory management, logistics, demand forecasting, production planning, and supplier relationships to improve efficiency, reduce costs, and enhance visibility throughout the supply chain. SCM software is essential for companies to automate and improve processes within their supply chains.

Supply chain management software can streamline your supply chain tasks. This will improve your supply chain efficiency, reduce supply chain costs, and allow you to manage vast amounts of data.

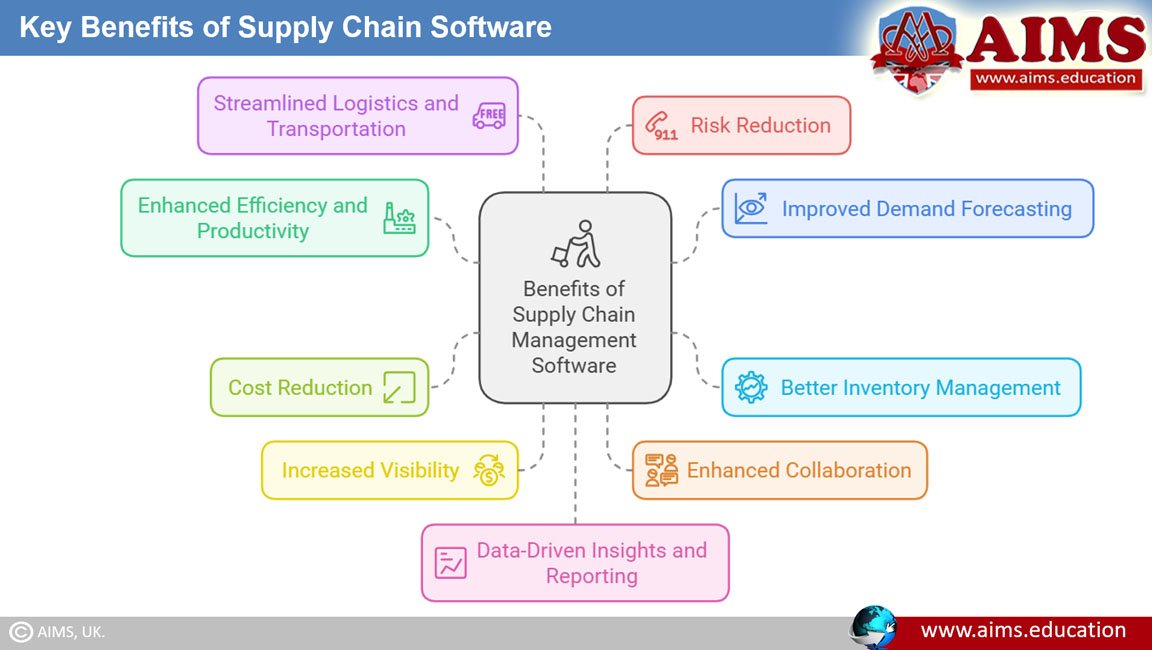

12 Key Benefits of Supply Chain Management Software

1. Enhanced Efficiency and Productivity:

They automate and optimize your routine tasks and reduce manual effort. Supply chain management software also improves overall productivity across your supply chain.

2. Improved Demand Forecasting

The supply chain software uses historical data and predictive analytics to accurately forecast demand, reducing the supply chain management risk related to stockouts or overstocking.

3. Better Inventory Management

These software tracks real-time inventory levels and ensures optimal stock levels, which leads to lower holding costs and improved cash flow in the supply chain management processes.

4. Cost Reduction

Supply chain management software helps you optimize procurement, warehousing, and transportation processes from production to delivery.

5. Increased Visibility

SCM software provides end-to-end visibility into the supply chain and enables better decision-making and quicker response when there are supply chain disruptions.

6. Enhanced Collaboration

The supply chain software also facilitates communication and data sharing among the supply chain partners, including: suppliers, manufacturers, distributors, and retailers. This helps smoother supply chain management operations and stronger partnerships.

7. Streamlined Logistics and Transportation

The supply chain management software helps manage routes, carriers, and shipments more effectively. This reduces lead times and ensures on-time deliveries.

8. Risk Reduction

They help you monitor potential disruptions in your supply chains and help you respond quickly to unexpected issues in order to maintain continuity.

9. Data-Driven Insights and Reporting

They can analyze vast amounts of data across the supply chain, which enables your company to make informed decisions, thus improving supply chain performance.

10. Improved Customer Satisfaction

With the help of supply chain software, you can ensure accurate, timely order fulfillment. This leads to better customer service and enhanced satisfaction.

11. Sustainability

This software also helps you optimize your company resource usage. That ultimately reduces carbon footprint and works towards more sustainable supply chain management practices.

12. Regulatory Compliance

Some supply chain management software offers features that allow companies to stay compliant with industry regulations and standards.

14 Types of Supply Chain Management Software

Supply chain management software can be divided into a variety of categories. Supply chain graduates who study the supply chain diploma or MBA in supply and logistics management develop skills in these systems to manage specific processes. Let us review the key types of supply chain management software:

1. Transportation Supply Chain Management Software

A Transportation Supply Chain Software (TMS) enables companies to manage the movement of goods efficiently. These types of software are crucial to optimize logistics operations, which include Planning, tracking shipments, and selecting carriers.

Here are the primary features and benefits of transportation software in the supply chain:

- Routing Guide: Supply chain software for transportation uses a routing guide to select the optimal transportation mode and carrier, which they calculate using your given shipment details.

- Freight Analysis: This supply chain management software also analyzes historical freight data and forecasts future shipping needs based on that data. This analysis supports negotiations with carriers during the bidding processes.

- Carrier Management: TMS aids in monitoring carrier performance and secure contracts, which provides transparency and reliability for the management of logistics.

2. Warehouse Supply Chain Management Software (WMS)

A Warehouse Management Software manages inventory and storage within a warehouse. These types of software help you ensure that your stock levels are maintained accurately and that they process efficient orders.

Here are the features of the warehouse supply chain software:

- Inventory Tracking: They track inventory levels, which helps you reduce losses that may emerge due to overstocking or stockouts.

- Order Picking and Shipping: They also facilitate the picking of items for orders and organize your shipments.

- Blurring with Warehouse Execution Software Systems (WES): Many WMS solutions overlap with WES capabilities. However, both these types of software are used to manage order picking and packaging tasks.

4. Supply Chain Planning Software

Supply Chain Planning Software predicts future demand, which helps companies prepare accordingly and minimize stockouts or overproductions.

Here are the features of Supply Chain Planning Software:

- Forecasting: DPS uses historical sales data and economic indicators to create demand forecasts.

- Adjustable Forecasting Models: They use different supply chain planning methods and apply them based on the seasonality or volatility of demand for various products offered by your company.

- Inventory Management: Planning Supply Chain Software also supports inventory balancing, which is one of the most important benefits of supply chain management.

5. Material Requirements Planning Software (MRP)

Material Requirements Planning Software (MRP) supports the manufacturing processes by ensuring that necessary components are available for production.

The main features of material planning software are listed below:

- Production Scheduling: This software starts with a master production schedule, which outlines: When to produce? and, What to produce?

- Bill of Materials (BOM): MRP uses BOMs to identify the materials that your require to manufacture each product.

- Inventory Level Monitoring: The material requirements planning software for supply chain management automatically checks inventory levels and generates purchase orders to maintain supplies at an adequate level.

7. Distribution Requirements Planning Software (DRP)

DRPs are the essential supply chain management software for managing and designing the supply chain networks. They predict inventory needs and plan replenishment orders across multiple distribution centers. The key features of distribution planning supply chain software are:

- Demand Forecasting: DRP forecasts demand at each distribution point, which helps you prevent stockouts.

- Order Planning: This software considers lead times and order quantities to optimize inventory levels.

- Lot Sizes: They also determine optimal lot sizes to balance ordering frequency in accordance with the inventory carrying costs.

8. Labor Management Software (LMS)

Labor Management Software (LMS) tracks and optimizes workforce performance in warehouses and distribution centers in your supply chains. The important features of Labor Management Software are:

- Scheduling: LMS schedules shifts based on anticipated workload and help you prevent understaffing or overstaffing.

- Performance Metrics: They also track worker productivity and also identify areas for training and skill development.

- Cost Reduction: LMS helps you minimize your labor costs by optimizing the workforce size and maximizing the efficiency of labor working in your supply chain.

9. Customer Relationship Management Software (CRM)

CRM systems are used in supply chains to enhance customer interactions, track purchase histories, manage orders, and identify new sales opportunities. The key features of CRM Supply Chain Software are as follows:

- Sales Forecasting: You can track current sales pipelines and improve your sales predictions.

- Targeted Marketing: They also enable supply chain management businesses to tailor communications and promotions to specific customer needs.

- Customer Insights: CRM software uses data on customer preferences and analyzes this data, which can help you foster stronger relationships with your customers.

10. Supplier Relationship Management Software (SRM)

These are the type of supply chain management software that helps you maintain supplier information and assist your company in managing and knowing the performance of your suppliers.

The key features of SRM software are as follows:

- Supplier Tracking: You can track your supplier’s contacts, contracts, and payment terms.

- Performance Analysis: This SCM software can also evaluate your supplier’s reliability and responsiveness.

- Risk Assessment: SRM identifies high-risk suppliers and suggests alternate suppliers.

11. Enterprise Resource Planning Software (ERP)

ERP software consolidates various SCM functions into a single, integrated platform. It means that you can seamlessly communicate across multiple departments. The key features of ERP supply chain software are:

- Process Automation: ERP automates numerous processes, from production planning to inventory replenishment.

- Data Integration: They connect with multiple modules and make data accessible across the organization.

- Customization and Complexity: ERPs are highly customizable. However, they require huge investments and may require significant configuration efforts.

12. Supply Chain Modeling Software

Supply Chain Modeling software allows companies to simulate, visualize, optimize, and design supply chain networks. The important features of supply chain modeling software are as follows:

- Digital Twins: This software creates virtual replicas of physical assets for enhanced visibility and scenario testing.

- Simulation: They can test different configurations and enable efficient adjustments to meet demand changes.

- Optimization: SCMS recommends layout and resource allocation to enhance productivity and service levels.

13. Business Intelligence (BI) Software

BI supply chain software is used to analyze data across the supply chain. They can connect to multiple data sources to enable comprehensive supply chain management analysis. The key features of BI software are:

- Real-Time Monitoring: Dashboards with real-time updates on supply chain performance.

- Insights for Optimization: Identify trends, inefficiencies, and performance benchmarks.

14. Supply Chain Risk Management Software (SCRM)

Supply chain risk management software can identify potential disruptions in the supply chain and then alert companies about events that may impact their business. Here are the key features of SCRM:

- Event Monitoring: Track events such as natural disasters or political unrest that may affect suppliers.

- Impact Analysis: Assess how disruptions can impact various supply chain segments.

Integration of Supply Chain Management Software

Integrating supply chain management software is a significant challenge due to differences in data formats and information storage across different systems.

However, integration in supply chain software is often facilitated through the following:

- Application Programming Interfaces (APIs) allow systems to exchange information by following set rules.

- Data Integration Hubs tools consolidate data from different systems to simplify the supply chain software integration.

Future of Supply Chain Management Software

The field of supply chain management software is moving from merely planning tasks to automating task execution. The eventual aim is to achieve fully autonomous supply chains through digital transformation and artificial intelligence. This future evolution is expected to streamline and optimize supply chains further, potentially reducing the need for human intervention in routine processes.