What is Supply Chain Network Design?

The success of any supply chain network will depend on the manufacturing plants, suppliers, warehouses, and how the product flows from each of the origins to the final customer. For any successful supply chain, the number of facilities and their locations are a critical factor. In fact, 80 percent of the operational costs of the supply chain networks depend on where the facilities are located and the product flows between them. To cut costs, you need a more systematic design approach so that you can plan and design the network efficiently. That is why the network design in the supply chain is so important.

Supply Chain Network Design is defined as: “A systematic approach to determining the best location and optimal size of the facilities to be included in the supply chain, and to ensure an optimal flow of products using advanced mathematical modelling”.

Importance and Role of Network Design in Supply Chain

The supply chain network structure of any company will determine how efficient its processes are and whether it is able to provide its customers with a great experience. Designing the most efficient supply chain networks requires the network to satisfy the supply chain strategies of the company over an extended period of time.

The role of network design in supply chain business involves the following:

- Defining the business objectives.

- Defining the project scope.

- Determining the analyses to be performed.

- Determining the tools to be utilized.

- Completion of the project in accordance with the design.

The supply chain network design determines the path ahead for the business. If the supply chain networks are designed and completed in accordance with the supply chain management of the company, the business can expect to gain in a substantial way.

How to Optimize Supply Chain Networks?

The first step in supply chain network design is to collect the data specific to the business, construct a basic model based on that, and validate the same.

The supply chain network design models include outputs such as the total costs, which are the same as those in real world operations. First the basic model is validated and then depending on the results an alternative design is created or the existed one modified for cutting costs further and increasing profits.

The construction of the supply chain network design models is handled by highly skilled consultants who collect high quality data, validate the model and propose alternative solutions.

7 Key Factors That Influence Supply Chain Network Design Decisions

Here’s a look at the critical factors for network design in supply chain.

1. Location and Distance

Distance between the different locations of the supply chain and the locations themselves are important factors to be considered. The location of the supply chain network includes customers, suppliers manufacturing abilities, airports, ports and so on.

2. Current and Future Demand

The current and future demands of the company are taken into account as well and should be grouped appropriately.

3. Service Requirements

The maximum allowable transit time and distance are used to determine the location of the warehouses to be added to the supply chain.

4. Size and Frequency of Shipment

The size and frequency of the shipment are essential factors for determining the supply chain and logistics costs and how to reduce them – the higher the frequency, the greater the cost; the smaller the shipment, the higher the cost.

5. Warehousing and Labour Costs

Warehousing costs are fixed costs and are factored into the decision-making process. The labor costs are not fixed, and they play a role as well.

6. Trucking Costs

The cost and type of trucking are of considerable importance.

7. Mode of Transportation

The other mode of transportation you will use to run the supply chain also matters.

Supply Chain Network Design Models

Supply chain network design models are strategic tools, that are used to optimize the structure and operation of supply chains. Following are the six supply chain design models that are widely used:

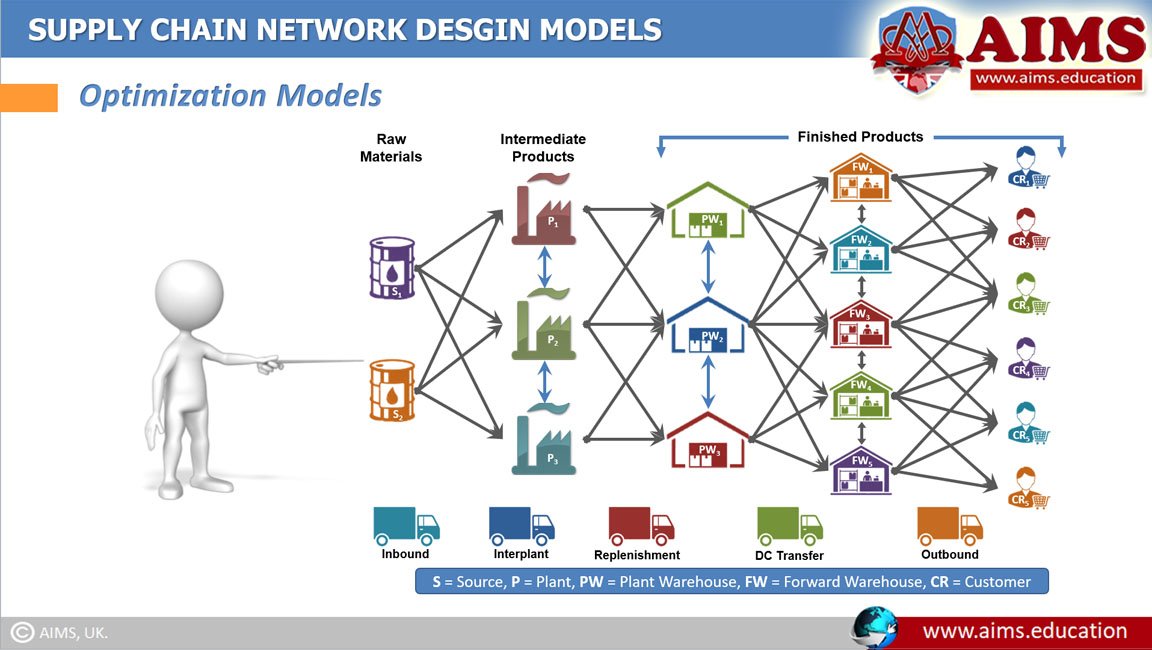

1. Optimization Models

- The optimization model is a mathematical model designed to identify the most efficient network by minimizing costs or maximizing profits.

- This supply chain model often incorporates variables such as shipping costs, production capacities, and customer demand.

2. Simulation Models

- The simulation model involves creating a digital twin of the supply chain to test different scenarios and predict outcomes.

- This supply chain network design model helps you understand the potential impact of network changes, such as demand fluctuations or supply disruptions.

3. Heuristic Models

- Heuristic models employ rules of thumb or algorithms to quickly find the right supply chain design for your network.

- The heuristic model is particularly useful for complex networks where traditional optimization methods may be computationally prohibitive.

4. Analytical Models

- The analytical supply chain network design model usus analytical techniques to perform a detailed examination of supply chain components and their relationships.

- These components may include queuing theory, inventory theory, or transportation models to optimize specific aspects of the supply chain network.

5. Hybrid Models

- The hybrid model combines the elements of optimization, simulation, and heuristic approaches.

- This model aims to leverage the strengths of each method to deliver robust, flexible, and scalable supply chain solutions.

Selection of the right supply chain network design model depends on your specific needs, and complexities of your supply chain. It depends on several factors, such as:

- The relationship management approach of supply chains.

- Efficiency and sustainability, such as green supply chain management.

- How will information and goods flow in your supply chains, your focus on global supply chain management, the analytical techniques regarding your supply chain, methods for reverse logistics, the supply chain framework that you are using, etc.?

Supply Chain Network Analysis

The purpose of Supply Chain Network Analysis is to design an optimal supply chain and improve the organization’s ability to make more tactical and strategic decisions. AIMS’ diploma in supply chain and supply chain management certification are among the globally recognized supply chain management qualifications, where students learn to analyze, plan, design, and manage global supply chains.

Supply chain network analysis makes use of a Big Picture Thinking approach to the supply chain network design from the conceptualization to the implementation. The supply chain network analysis is focused on determining the distribution nodes based on factors such as demand concentration, customer locations, and service requirements.

How to Design a Global Supply Chain Network? 9 Steps Process

Businesses are no longer just local in the days of globalization and supply chains have to be global in the way they operate as well. In addition to the factors discussed above, global supply chain networks include other factors such as the difference in culture, language and currencies. Transportation, software compatibility and the cost of fuel or oil are also considered.

Here are the necessary steps involved in supply chain network design:

Step 1: Define Objectives and Goals

In this step, you establish the primary objectives of the supply chain network design, such as cost reduction, improved delivery times, or enhanced customer satisfaction.

Step 2: Analyze the Supply Chain Environment

Assess the current market conditions, customer demands, and competitor activities. Identify potential supply chain management risks and opportunities.

Step 3: Gather Data

Collect detailed data on suppliers, production facilities, warehouses, distribution centers, transportation options, and customer locations.

Step 4: Develop Supply Chain Scenarios

Consider various supply chain network models and scenarios to understand different logistics and distribution strategies, and choose the one that suits you.

Step 5: Optimization

Use optimization techniques to determine the most efficient placement of facilities and the best routes for transportation. This could involve mathematical modeling and supply chain network design software tools.

Step 6: Evaluate and Compare Models

Analyze the cost, efficiency, and feasibility of each model. Consider factors such as infrastructure capabilities, labor availability, and geopolitical stability.

Step 7: Select the Best Network Design

Choose the supply chain network design that meets the set objectives and goals while offering the best balance of cost and supply chain network performance.

Step 8: Implementation Plan

Develop a detailed plan to implement your chosen supply chain network. The supply chain plan must include timelines, resources, and responsibilities.

Step 9: Monitor and Review

Regularly review the performance of the supply chain network and make adjustments as needed to respond to changing conditions and continuous improvement. Ensuring a well-thought-out supply chain network design can significantly enhance operational efficiency and adaptability of your supply chain, in today’s dynamic market.

What is a Supply Chain Network Design Software?

Supply chain network design software is essential for managing the entire supply chain. Here are some of the key features offered by most of the supply chain management software:

- Design and analyze a supply chain, from initial planning to production and shipment.

- Track inventory levels, monitor delivery progress, and optimize logistics.

- Integrate data from multiple sources to better understand how products move through your supply chain and identify opportunities for optimization.

- It can also help your avoid bottlenecks, which can lead to shipment delays and increased costs.

Frequently Asked Questions

Q1: What is supply chain network design?

It’s a systematic method to decide the optimal number, size, and location of facilities and product flows using analytical and mathematical modelling.

Q2: Why does network design matter in supply chains?

Facility placement drives most operating costs and service. Strong designs lower cost-to-serve, shorten lead times, and boost resilience.

Q3: What factors influence network design decisions?

Location and distance, current and future demand, service requirements, shipment size/frequency, warehousing and labour costs, trucking costs, and transport modes.

Q4: Which modelling approaches are commonly used?

Optimization, simulation, heuristics, analytical models, and hybrid approaches that blend speed with accuracy and scalability.

Q5: How do I start a network design project?

Define objectives and scope, gather clean data, build and validate a baseline model, then iterate scenarios to compare results.

Q6: What is the 9-step global network design process?

Set goals, analyse environment, gather data, develop scenarios, optimise, evaluate, select, implement, and monitor for continuous improvement.

Q7: How do service targets affect warehouse placement?

Transit time and distance SLAs dictate how many warehouses you need and where they must be to hit delivery promises.

Q8: How do shipment size and frequency impact costs?

Frequent, small shipments raise per-unit transport and handling costs; balancing lot size and cadence reduces total logistics spend.

Q9: What features should network design software offer?

Facility and flow modelling, optimisation, scenario testing, multi-source data integration, inventory tracking, and delivery monitoring.

Q10: How do we keep the network optimal over time?

Track KPIs, refresh data, re-run scenarios when demand or costs shift, and execute changes through a governed review cycle.