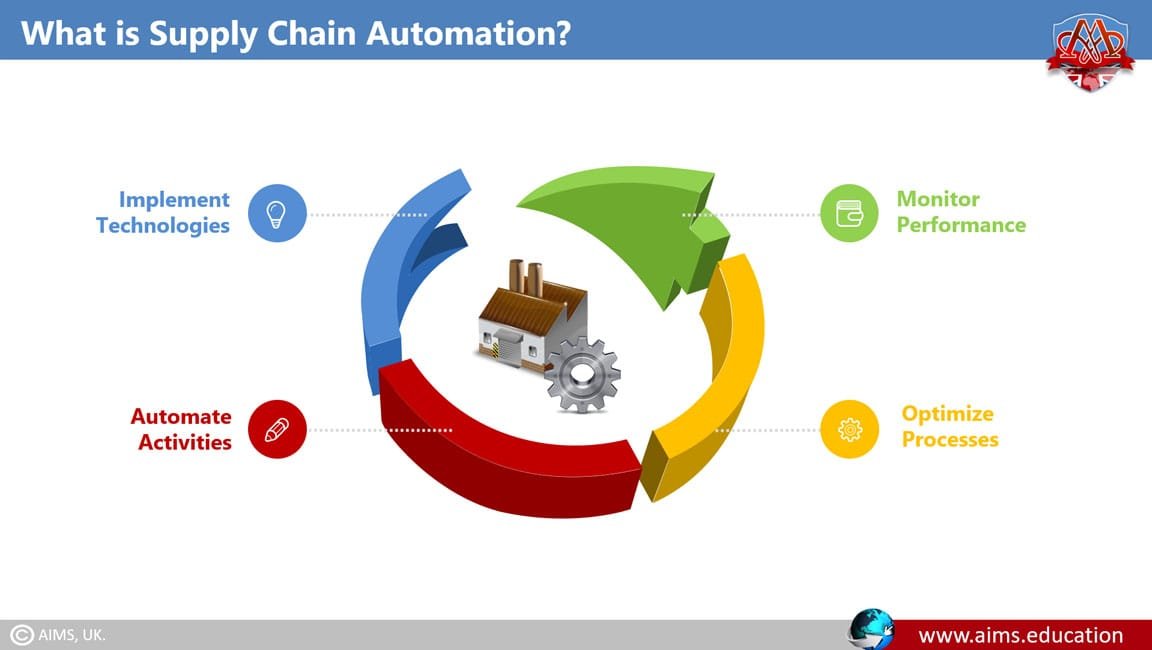

What is Supply Chain Automation?

Supply chain automation is a process which uses machine learning, artificial intelligence (AI), and other digital technologies to perform supply chain activities with minimal or no human intervention. Automation in supply chain operations can take various forms; for example, Internet of Things (IoT) tools can automate physical processes on the manufacturing shop floor. Similarly, robotic process automation in supply chain and intelligent document processing are used to automate digital workflows in both production and back-office functions.

What are Supply Chain Automation Solutions?

Supply chain automation solutions are essential for businesses aiming to operate efficiently and competitively. Supply chain automation solutions enhance efficiency (delivery speed) and cost effectiveness, improve product consistency, and increase output quality.

For Example

When companies implement automation in supply chain tasks, they can produce higher volumes of quality products more quickly and reliably. It gives them a competitive edge in the market.

How to Apply Automation in Logistics and Supply Chain Management?

Supply chain automation is applied across many logistics and supply chain processes. Below are a few key use cases:

1. Inventory Automation

Traditionally, inventory registration of goods was done manually or using basic tools, which were prone to errors. However, automation in supply chain management now optimizes warehousing through AI-powered systems that integrate data, forecast demand, and generate purchase orders to manage inventory levels efficiently.

Real-World Example:

Amazon uses AI-driven robots in warehouses to automatically scan, move, and update inventory data in real time. This reduces errors and speeds up order fulfillment.

2. Back-Office Automation

Supply chain automation enhances back-office operations by reducing human error and operational costs. It captures data from orders without manual input and automatically enters it into the system. Robotic process automation in supply chain workflows significantly improves data accuracy and processing speed.

Real-World Example:

Maersk, a global shipping company, uses RPA to automate invoice processing, which reduces turnaround time by over 80%.

3. Logistics Automation

Technology enables supply chain automation solutions to manage package delivery, route planning, and communication among supply chain stakeholders. E-commerce platforms, for example, utilize delivery tracking tools to meet customer expectations. GPS tracking systems and real-time delay notifications ensure transparency and enhance the delivery experience.

Real-World Example:

FedEx uses automated route optimization and real-time GPS tracking to improve delivery accuracy and notify customers about delays instantly.

4 Key Benefits of Supply Chain Automation

In today’s increasingly digitalized world, supply chain management businesses that adopt automation in supply chain operations gain a significant edge over competitors. Below are four key benefits of automation in supply chain management:

1. Flexibility

Supply chain automation reduces human error and operational disruptions, which enables companies to respond more quickly and flexibly to shifting market demands.

For Example

Zara, the global fashion retailer, uses automated inventory and distribution systems. These systems allow the company to launch new designs and restock stores in just 2–3 weeks, significantly faster than the industry average of 6–9 months.

2. Data-Driven Decisions

Automation in the supply chain enables accurate demand forecasting, real-time tracking, and smarter resource planning. These capabilities support data-driven decisions, which reduce costs and improve performance.

For Example

Procter & Gamble (P&G) integrated AI and machine learning into its supply chain. It resulted in a 20% reduction in supply chain costs and 95% forecast accuracy, according to a 2022 McKinsey report.

3. Transparency

Traditionally, gaining end-to-end supply chain visibility was a challenge. Now, supply chain automation solutions provide real-time data access across departments, aligning all stakeholders and simplifying processes.

For Example

Unilever implemented a digital control tower to monitor its global supply chain. This system improved transparency and allowed the company to proactively manage disruptions. This improved the company’s on-time delivery by 10%, as per Deloitte Insights.

4. Customer Satisfaction

AI-powered tools enhance the customer experience by improving order accuracy and reducing delivery times. Automated supply chain systems for last-mile and long-haul logistics enable dynamic route planning and real-time updates.

For Example

UPS uses its ORION (On-Road Integrated Optimization and Navigation) system, which saves 100 million delivery miles annually, cuts delivery times, and improves customer satisfaction.

Supply chain automation is a core discipline in modern supply chain and logistics education. Students pursuing a diploma in supply chain or our accredited MBA in Supply Chain and Logistics management study the future of supply chain automation in depth to build cutting-edge skills for the global marketplace.

Types of Supply Chain Automation Solutions

Businesses are complex ecosystems with dedicated tools for each supply chain function. When these processes are interconnected and visible in real time, issues like stockouts and delays can be addressed proactively. Below, we discuss five types of supply chain automation solutions, each designed to enhance specific operations and improve overall supply chain efficiency.

1. Procurement and Sourcing Automation Software

a. Supplier Management

The supply chain process begins with procurement and sourcing, where effective supplier management is essential. Supply chain automation introduces tools like B2B vendor portals, which allow businesses to automate supplier selection and contract management using AI and machine learning. These tools evaluate vendors based on quality, compliance, reliability, and cost, helping businesses make data-driven decisions.

b. Order Management

In this stage, robotic process automation in supply chain operations handles tasks such as: generating purchase orders, matching invoices, and automating payments. This reduces manual errors and accelerates processing time, which enables a seamless automated workflow from order creation to payment completion.

c. Contract Management

Blockchain supply chain based automation in supply chain ensures a centralized, secure, and transparent contract management system. It supports compliance monitoring, contract renewals, and minimizes legal and operational supply chain management risks.

d. Real-Time Data and Analytics

Supply chain automation software delivers real-time insights into spending, supplier performance, and market trends, which allows you to improve strategic procurement planning.

e. Collaborative Platforms

Automation tools enable collaborative dashboards through IoT integration, enhancing communication between businesses and suppliers.

2. Production Planning and Execution Management

Supply chain automation systems, such as Enterprise Resource Planning (ERP), are essential for optimizing production processes with precision and control.

a. Scheduling and Resource Allocation

Automated systems use advanced algorithms to create dynamic production schedules, allocate resources efficiently, and respond quickly to changes in demand or supply.

b. Real-Time Monitoring and Control

IoT-enabled devices provide a comprehensive view of the production floor. This enables real-time tracking, quick troubleshooting, and consistent quality assurance.

c. Simulation of Production Environment

Digital twin technology enables the simulation of production scenarios in a virtual environment. It allows companies to test process changes, improve supply chain agility, and reduce risk in complex manufacturing operations.

d. Integration

Automation in supply chain processes links procurement, production, and warehouse functions via customized supply chain software platforms, ensuring seamless coordination.

e. Predictive Analytics and Maintenance

AI-powered predictive analytics can forecast equipment failures, prevent downtime, and enhance operational continuity.

3. Warehouse Management Tools

Warehouse automation boosts efficiency, accuracy, and responsiveness in inventory management.

a. Inventory Management

Warehouse Management Systems (WMS) and cloud-based inventory tools streamline inventory tracking and storage decisions.

b. Optimize Stock Conditions

IoT-integrated sensors monitor and regulate environmental conditions, such as temperature and humidity, minimizing damage and spoilage.

c. Data Analytics

AI-driven supply chain management analytics identify demand patterns, control inventory levels, and avoid overstocking or stockouts, which are among the key benefits of automation in supply chain.

d. Order Fulfillment

Automation in supply chain warehouses supports the picking, packing, and shipping processes through tools that enhance speed and accuracy.

e. Logistics Management

WMS platforms integrate with logistics management processes to optimize delivery routes using AI-based route planning, which ensures faster and more economical shipments.

4. Transportation and Delivery Automation Tools

Efficient transport and timely delivery are vital to building customer trust. Below are key tools used in the future of supply chain automation:

a. Automated Route Optimization

Tools use real-time data, including traffic and weather, to choose optimal delivery routes. This reduces fuel use, wear and tear, and delivery times.

b. Automated Fleet Management

These systems provide real-time vehicle tracking, manage driver performance, and schedule preventive maintenance, enhancing safety and efficiency.

c. Automated Dispatch and Scheduling

AI-based scheduling tools match deliveries with available drivers and vehicles. This improves operational flow and delivery accuracy.

d. Real-Time Tracking and Visibility

Supply chain automation tools enable logistics teams and customers to track shipments, manage disruptions, and enhance delivery transparency.

5. Customer Service and Returns Automation Software

Automation improves post-purchase interactions, which play an important role in customer satisfaction and loyalty.

a. Automated Handling of Customer Inquiries

AI-powered chatbots respond instantly to FAQs and route complex queries, which maintains consistent communication.

b. Automated Returns and Exchanges

Automation simplifies reverse logistics process by generating return labels, sorting products, and guiding customers through the process efficiently.

c. Order Tracking

Customers can monitor their orders in real time. This increases confidence and reduces support queries, which is one of the key benefits of automation in supply chain management.

d. Feedback Management

AI analyzes customer feedback from multiple sources (e.g., surveys, emails, social media), categorizes responses, and helps businesses identify recurring issues and improve service.

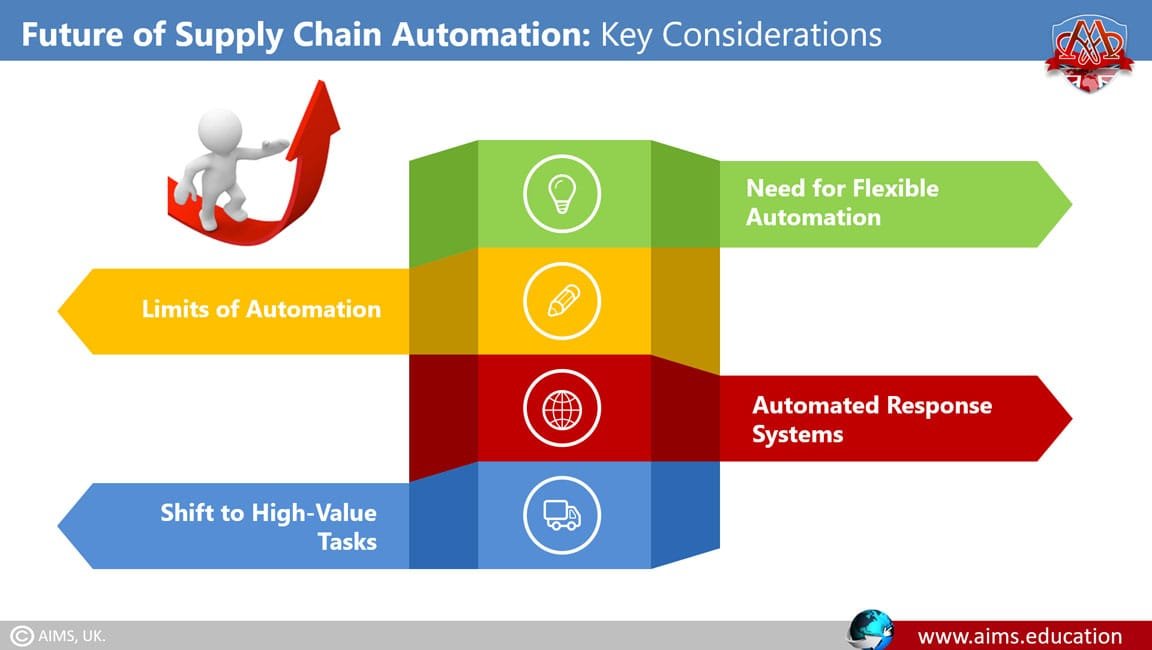

Future of Supply Chain Automation

1. Rising Complexity and the Need for Flexible Automation

A supply chain includes all the activities involved in the manufacturing, movement, and delivery of goods, connecting manufacturers, suppliers, logistics providers, and end customers. As the supply chain management network becomes more complex, it continues to face challenges such as supply disruptions, labor shortages, and shifting customer expectations. Therefore, adopting reliable and flexible supply chain automation solutions is critical.

2. Automated Response Systems and Real-Time Agility

When companies implement automated customer response systems, teams can adapt quickly, which improves overall supply chain agility.

For Example

- If a procurement manager detects a potential shortage, automation can trigger pre-set actions such as ordering replenishments or initiating alternative sourcing strategies.

- If a supplier fails to meet deadlines, the system can automatically identify alternate suppliers or authorize expedited freight, thereby minimizing disruption.

3. Limits of Automation and the Role of Human Labor

Supply chain automation increases efficiency and responsiveness, offering advanced tools to predict, plan, and respond to changes in a dynamic global environment. However, it is important to note that full automation does not entirely eliminate the need for human involvement. In the absence of fully autonomous transport infrastructure, the supply chain will continue to rely on truck drivers, ship crews, and airline staff to complete critical logistics operations.

4. Smart Workflows and the Shift to High-Value Tasks

As the future of supply chain automation evolves, businesses must embrace smart workflows and integrate cutting-edge automation technologies that eliminate manual, time-consuming tasks.

For Example: Automated inventory management is far more accurate and efficient than traditional methods.

By leveraging these technologies, employees can shift focus to high-value tasks, such as strategic supply chain planning and relationship management in supply chain management, thereby boosting productivity across the supply chain.

Frequently Asked Questions

Q1: What is supply chain automation?

It uses software, AI, RPA, sensors, and robotics to automate planning, sourcing, production, warehousing, transport, and order management.

Q2: What are the main benefits?

Greater flexibility, better decisions, end-to-end visibility, and higher customer satisfaction via faster, more reliable fulfilment.

Q3: Which processes are ideal to automate first?

Procurement, demand planning, production scheduling, inventory control, warehouse tasks, route optimisation, tracking, and returns.

Q4: Which tools enable automation?

ERP, APS, WMS, TMS, control towers, digital twins, predictive analytics, and supplier collaboration platforms.

Q5: How does warehouse automation help?

It streamlines picking, packing, and shipping, maintains stock conditions with IoT, reduces errors, and boosts inventory accuracy.

Q6: What’s AI’s role?

AI predicts demand, flags anomalies, prevents equipment failures, and recommends actions that raise service levels and cut costs.

Q7: How do digital twins improve production?

They simulate scenarios to test changes, optimise resources, and reduce risk before real-world deployment.

Q8: Can you share real examples?

Zara uses automated inventory flows; UPS deploys ORION routing; FedEx uses GPS-enabled tracking; Unilever runs control towers.

Q9: Where does automation fall short?

Complex exceptions, regulatory steps, and nuanced customer interactions still require human judgment and oversight.

Q10: How do we start an automation roadmap?

Identify pain points, prioritise high-ROI use cases, standardise data, integrate ERP/WMS/TMS, pilot, then scale.