What is Supply Chain Analytics?

In today’s globalized economy, supply chains have become increasingly complex, with goods moving across international borders from multiple locations. As a business manager, it is essential to conduct effective supply chain analysis to optimize and adapt your supply chain according to your business needs. While a supply chain may initially seem efficient, it may prove ineffective once operations begin. This is why you need to leverage supply chain analytics using the right supply chain analytics tools and software to detect any inefficiencies or potential disruptions before they impact your operations.

What is Supply Chain Analytics Process?

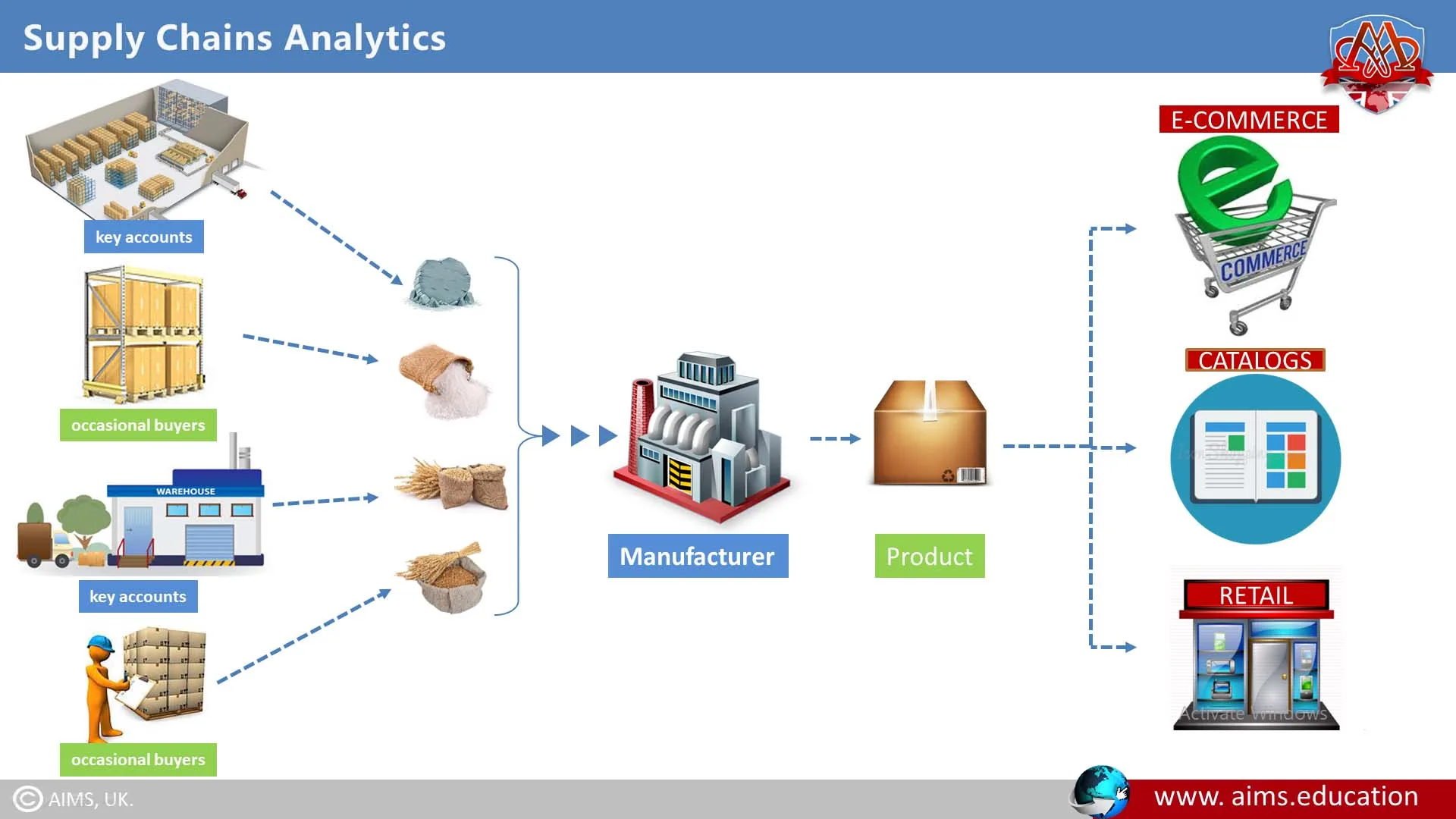

Supply chain analytics is the systematic process of collecting, analyzing, and interpreting data to evaluate your supply chain’s performance and identify areas for improvement. Every business operates within a broader supply chain network, and supply chain analytics enables organizations to uncover opportunities for efficiency gains, cost reduction, and business growth.

Supply Chain Analytics Tools and Models

With the help of supply chain analytics tools, businesses can gain full visibility into everything: From raw material availability and pricing to transportation, logistics, final product distribution, and customer demand. In other words, supply chain analytics tools not only help you understand the internal functioning of your supply chain but also enable you to identify potential business partners, whether for sourcing raw materials or expanding sales channels. Ultimately, these insights contribute to the strategic growth of your company.

Below are five widely used supply chain analytics tools and models:

1. Descriptive Analytics

This is one of the most common types of supply chain management analytics used to analyze past performance. It informs you of what has happened, and allows you to assess whether the results align with your original plans and objectives. Descriptive analytics leverages data mining to collect raw data from across the supply chain, summarize it, and present it in a clear, concise format to provide insights into historical trends and performance.

2. Predictive Analytics

If you want to forecast future events, predictive analytics is the appropriate supply chain analysis tool. As the name suggests, it creates data-driven models that simulate potential scenarios that may occur in the coming weeks, months, or even years. While exact outcomes cannot be guaranteed, predictive analytics provides probabilistic insights that enable better planning and risk mitigation.

3. Prescriptive Analytics

Prescriptive analytics not only predicts what may happen but also recommends optimal courses of action based on those predictions. This tool uses advanced algorithms and simulation models to suggest data-backed decisions if specific scenarios unfold. It supports proactive, rather than reactive, decision-making in supply chain management.

4. Performance Metrics

This is one of the best supply chain analysis tools, to use when you want to see how the supply chain planning and the chain itself is performing. Just do keep in mind that there are several metrics, and each of them provides a different type of information. So, you need to decide which supply chain management metrics are most useful and relevant to your business so you can keep an eye on those in particular.

5. Hybrid Performance Measurement

This is one of the most valuable supply chain analytics tools when assessing how your supply chain planning and execution are performing. A variety of supply chain metrics can be monitored, such as: order cycle time, fill rate, inventory turnover, and forecast accuracy. It is crucial to select the most relevant metrics for your business to track and continuously improve supply chain management performance.

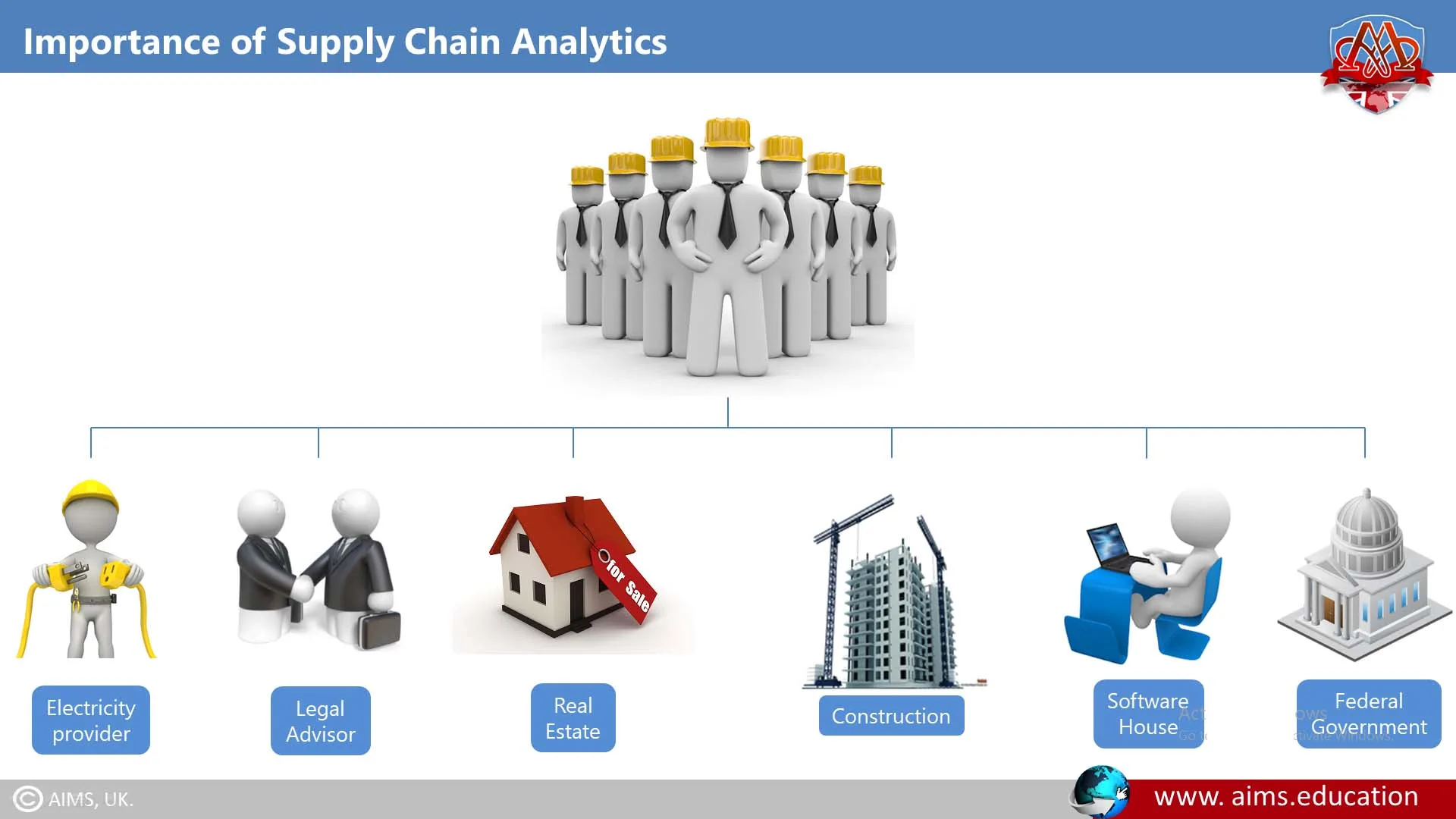

Importance of Supply Chain Analytics

The main purpose of supply chain management is to coordinate various players involved in the supply chain to deliver products to customers efficiently and effectively. As a supply chain manager, you must regularly perform supply chain analysis to identify potential problems or inefficiencies.

- Supply chain analytics helps collect and interpret data to support better decisions and improve overall business performance.

- With the right supply chain analytics tools, you can identify and solve problems in procurement, transportation, inventory management, and customer service.

Supply chain analysis and analytics are integral components of AIMS’ logistics certification course and CSCE, which is a globally recognized supply chain management certification program. AIMS offers these logistics and supply chain management courses online through a flexible, self-paced, and interactive learning system.

6 Key Data Components of Supply Chain Analysis

Data is the key to supply chain management analytics. Various components of the supply chain produce data that is gathered and analyzed. Here is the importance of supply chain data:

- The data helps you dig deeper into the supply chain to examine efficiency gaps and improve the operational, financial, and managerial aspects of logistics and supply chain management.

- It helps businesses capture and study a large amount of information.

- Supply chain data is collected and visually displayed through charts and graphs for better insights.

Organizations should understand the following components of their supply chain data before applying supply chain analysis tools:

DATA SOURCES

- Where do your data sources come from?

- How can you ensure the data is accurate and reliable?

DATA TYPES

- What types of data are essential to your supply chain?

DATA AVAILABILITY

- Is the data available in a timely manner?

- Can it be accessed by all members of the supply chain team?

DATA OWNERSHIP

- Who is responsible for collecting and analyzing data?

- Who owns this data?

DATA SECURITY AND PRIVACY

- How is the data secured?

- Are there any relevant compliance requirements?

DATA ANALYSIS CAPABILITIES

- What supply chain analytics tools are you using to analyze data?

- What types of reports and visualizations are you creating?

Supply Chain Analytics Examples

1. DHL

- In 2018, DHL hired qualified professionals with doctorate in logistics and supply chain management and partnered with Riddle & Code for their supply chain analysis and customer experience improvement using tools for blockchain supply chain management.

- Through this partnership, DHL was able to track individual shipments in real-time.

2. SWEDISH RAILWAY

- Swedish Railway partnered with SAP to enhance its ability to manage its global supply chain.

- The insights gained from supply chain analysis enabled the railway to optimize procurement, logistics, and asset management for better efficiency.

3. E.ON

- E.ON, a global electricity and gas company, engaged SAP to improve and recommend innovations in its supply chains.

- Data collected via their supply chain management automation platform was analyzed, which helped them improve energy management and customer service.

3 Tips to Improve Your Supply Chain Analytics Strategy

The following are 3 tips to improve your supply chain analytics strategy:

1. Star Small

- Prioritize projects that will have the greatest impact on the organization.

- Building a big data analytics project can be costly, time-consuming, and complex. So, start small with a few projects that have clear objectives and can be completed relatively quickly.

- This approach will help you gain experience and demonstrate value rapidly.

2. Focus on Data that Matters

- To be effective, supply chain analytics must be actionable. This means the data must be accurate and have a tangible impact on the supply chain.

- While all data has value, only data that is truly relevant should be collected and analyzed.

3. Build a Culture of Collaboration

- Supply chain analytics can provide value to organizations of all sizes and across diverse supply chain environments.

- For best results, create a collaborative culture where data is accessible to all members of your supply chain team.

Special Types of Supply Chain Analytics

Several special types of supply chain analytics are used to achieve organizational goals. For better understanding, here is a brief overview of three of them:

1. Capacity Planning

- Capacity planning is a type of supply chain analysis used to align manufacturing capacity with sales demand.

- Different supply chain analysis tools are used to create mathematical models, which analyze data to predict future sales capacity.

2. Simulation and Scenario Analysis

- Simulation and scenario analysis are types of supply chain analytics used for strategic planning to evaluate potential business scenarios.

- They help shape your company’s future and maintain stability during various crises.

3. Sales & Operations Planning

- Analysis for supply chain operations and sales focuses on the financial bottom line and helps determine the most profitable production levels.

- This type of supply chain management analysis is used to forecast sales scenarios and maximize future production.

Frequently Asked Questions

Q1: What is supply chain analytics?

It’s the structured use of data across procurement, production, logistics and demand to assess performance and drive improvements in cost, service and growth.

Q2: How does the supply chain analytics process work?

Define questions, map data sources, ensure availability and ownership, secure data, select tools, and deliver insights via reports and visualisations for action.

Q3: What are the main types of analytics tools?

Descriptive (past), predictive (likely future) and prescriptive (recommended actions), plus KPI frameworks and hybrid measurement models.

Q4: When should I use predictive vs prescriptive analytics?

Use predictive to forecast demand and risks; prescriptive to recommend optimal decisions based on predictions and constraints.

Q5: Which data components matter most?

Sources, types, availability, ownership, security/privacy and analysis capabilities—all defined with clear governance.

Q6: What are examples of supply chain analytics in practice?

DHL real-time tracking, Swedish Railway optimisation with SAP, and E.ON’s automation-driven improvements in energy management.

Q7: How do I start a supply chain analytics initiative?

Start small with high-impact use cases, focus on actionable data, and build a collaborative, cross-functional culture.

Q8: What mistakes should I avoid?

Data without decisions, poor data quality, siloed access, over-complex models and unfocused KPIs.

Q9: How do metrics and hybrid measurement help?

They align strategy to action via concise KPIs like order cycle time, fill rate, inventory turns and forecast accuracy.

Q10: Which special analytics approaches are useful?

Capacity planning, simulation/scenario analysis and S&OP for aligning demand, supply and finance.

Q11: Who should own supply chain data?

Business owners define KPIs, data teams manage quality and pipelines, and security/compliance enforces policies.

Q12: How do I choose analytics software?

Pick tools that integrate data sources, cover descriptive/predictive/prescriptive needs, visualise clearly, and meet security and skill requirements.