Closed Loop Supply Chain Meaning

A closed-loop supply chain (CLSC) aims to minimize waste and reduce costs by managing the entire life cycle of a product. It involves the forward flow of goods from supplier to customer and the backward flow of used or end-of-life products for reuse, recycling, or disposal. Closed loop recycling is a key concept in waste management, signifying a process where waste materials are not merely discarded, but collected, processed, and repurposed into new products, thus creating a ‘Closed Loop.’ The goal of Closed Loop Supply Chain Management (CLSCM) is to maximize the total value generated from the lifecycle of a product, minimize overall costs, and reduce environmental impact through recycling and waste reduction. It represents a paradigm shift from a linear economy to a circular economy, extending the product life cycle and promoting sustainable practices. By implementing a CLSC, companies can reduce their carbon footprint, and generate additional revenue streams.

“A closed loop supply chain (CLSC) refers to a business model that operates in a circular economy, where resources are used efficiently and waste is minimized. It involves the continuous flow of products from suppliers to customers, as well as the reverse flow of materials and products for reuse, recycling or disposal”.

Closed Loop Supply Chain Definition

Closed Loop Supply Chain VS Circular Economy

Transitioning from the concept of a closed loop supply chain, it’s critical to juxtapose it with the broader framework of a circular economy. While there are similarities between the two, they represent different perspectives.

- Thus, the closed-loop supply chain concentrates more on the operational processes involving the manufacture, consumption, and the loop back through the recovery and recycling of products. It is a specific, practical mechanism within the broader circular economy.

- In contrast, the circular economy is an economic system aimed at eliminating waste and the continuing use of resources. This wider perspective includes sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products as long as possible.

6 Stages of Closed Loop Supply Chain Life-Cycle

A closed loop supply chain involves multiple stages including product design, manufacturing, distribution, consumption, and reverse logistics. The goal is to create a continuous cycle where products are reused, refurbished, or recycled instead of being disposed of after use. This not only helps to minimize waste and reduce the impact on the environment, but it also creates opportunities for economic and social growth. Given below are the key stages:

Stage-1: Product Design

The first stage of a CLSC is product design. In this stage, companies take into consideration the entire life cycle of a product, including its potential for reuse, refurbishment, or recycling. This requires collaboration between designers, engineers, and supply chain experts to create products that are durable, repairable, and easy to disassemble. By designing for circularity, companies can ensure that their products have a longer lifespan and are easier to reuse or recycle.

Stage-2: Manufacturing

The next stage is manufacturing, where raw materials are transformed into finished products. Manufacturers in CSLP use sustainable materials and processes to reduce their environmental impact. They also incorporate design features that make it easier to disassemble and reuse products, such as using standardized parts and modular designs. By implementing these measures, manufacturers can minimize waste and create more sustainable products.

Stage-3: Distribution

Once the products are manufactured, they are then distributed using environmentally friendly methods such as electric or hybrid vehicles. In a closed loop supply chain, companies also consider the packaging materials used for their products and use sustainable alternatives when possible. This reduces the amount of waste generated during distribution and ensures that the entire supply chain is aligned with circular principles.

Stage-4: Consumption

At the end of a product’s life cycle, it is up to consumers to play their part in a closed loop system. Proper usage and disposal of products are crucial for ensuring that they can be reused or recycled. Consumers can also choose to support supply chain companies that have circular supply chains, encouraging more companies to adopt sustainable practices.

Stage-5: Reuse & Refurbishment

Products are designed with the intention of reuse and refurbishment in mind. This means that when a product reaches the end of its initial use, it can be refurbished or repaired and sold again. This not only reduces waste but also creates a market for second-hand goods and promotes a circular economy.

Stage-6: Recycling

When products can no longer be reused or refurbished, they can still be recycled to create new materials. Recycling is an important part of a closed loop supply chain, which ensures that valuable resources are kept in use for as long as possible. Companies can also incorporate recycled materials into their manufacturing processes, further reducing the need for new resources.

Additional Stages to Improve CLSC Life Cycle

a. Innovation

To continue improving and refining CLSC practices, innovation is key. This includes using new technologies and design methods to create more sustainable products, finding ways to reduce waste and improve efficiency in logistics, supply chain, and constantly seeking new ways to close the loop and keep resources in use. Companies that prioritize innovation can stay ahead of the curve and lead the way toward a more circular economy.

b. Collaboration

By working together and sharing knowledge, expertise, and resources, companies can overcome challenges and accelerate progress towards a circular economy. Collaboration can also lead to the development of new business models and partnerships that support closed-loop practices. A Closed Loop Value Chain, similar to the value chain, is an operational strategy that merges traditional forward supply chain operations with reverse logistics. The value creation process in a closed loop value chain is thereby cyclical, rather than linear, with resources continually being reused and recycled to create new products.

c. Consumer Education

Consumers play a crucial role in closing the loop by making informed purchasing decisions and properly disposing of products at the end of their life cycle. This requires education and awareness about what a closed loop supply chain is, why it’s important, and how consumers can contribute. Companies can help by providing clear information about the sustainability of their products and encouraging responsible consumption habits.

d. Government Support

Government policies and regulations can also play a significant role in promoting CLSC practices. This can include incentives for companies to use recycled materials, requirements for proper disposal or recycling of products, and funding for research and development of circular economy solutions. With government support, companies may be more motivated to invest in sustainable practices and technologies.

e. Technology Advancements

Technology is constantly evolving and can offer innovative solutions for closing the loop in supply chains. This can include advancements in recycling technology, tracking and tracing systems for materials, and data analytics to optimize processes and reduce waste. By embracing technology, companies can improve efficiency, reduce costs, and create more sustainable international supply chains.

f. Consumer Demands

As consumers become more conscious about the environmental impact of their purchasing decisions, they are demanding more sustainable products and transparent supply chain practices. This is putting pressure on companies to adopt circular practices and provide eco-friendly options. By listening to consumer demands and adapting to changing trends, companies can stay ahead of the game and build strong relationships with their customers.

g. Collaboration

Closing the loop in supply chains requires collaboration between all stakeholders, including manufacturers, suppliers, retailers, consumers, and waste management companies. By working together towards a common goal of sustainability in supply chain innovation, these parties can overcome challenges and find innovative solutions that benefit everyone involved. Collaboration also allows for knowledge sharing and learning from best practices in different industries.

h. Education

Education is crucial for creating a circular economy. Companies can educate their employees, suppliers, and customers on the importance of sustainability and how they can contribute to the enhanced role and importance of supply chains. This can include training on waste reduction, recycling practices, and responsible consumption. By educating stakeholders, companies can foster a culture of sustainability and create long-lasting change. An accredited MBA to specialize in supply chain management and a professional diploma in supply chain and logistics are well-recognized among the organizations to train their employees on the subject.

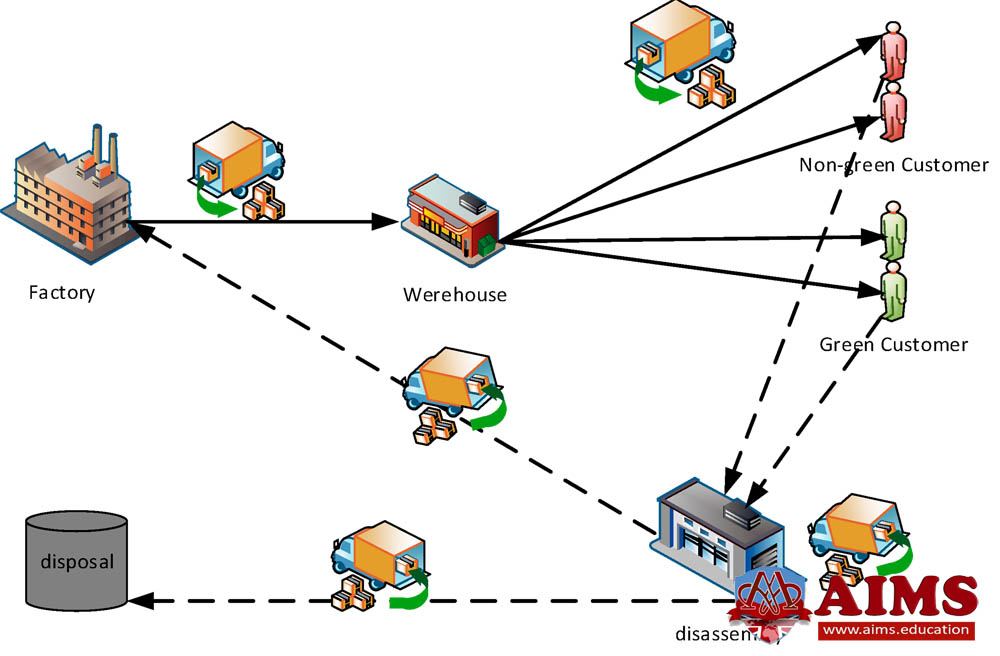

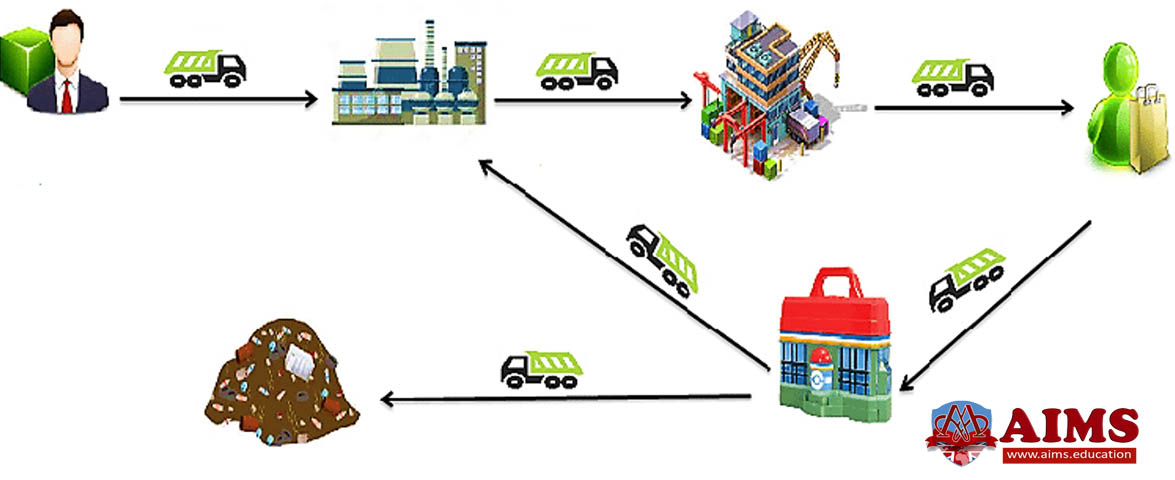

Closed Loop Supply Chain Diagram

The closed loop supply chain diagram consists of two main components:

- Forward flow, and,

- Reverse flow.

A. Forward Flow

The forward flow represents the traditional supply chain, where products are produced, distributed, and sold to customers.

B. Reverse Flow

The reverse flow, on the other hand, involves the recovery and recycling of used or end-of-life products. Here, the products can go through various processes such as remanufacturing, refurbishing, and recycling to be reintroduced into the supply chain. This reduces the need for new raw materials and minimizes waste, making it an environmentally friendly approach.

Best Practices for Closed Loop Supply Chain Management

Implementing the following best practices can help businesses effectively manage a closed loop supply chain:

1. Design for Sustainability

Incorporating sustainability into product design is crucial in a CLSC. This includes using environmentally friendly materials, designing products that are easy to disassemble and repair, and considering end-of-life options during the design phase.

2. Reverse Logistics

Reverse logistics involves managing the flow of materials from the consumer back to the manufacturer. Having a well-defined reverse logistics process is essential in a closed loop supply chain, as it allows for proper handling and disposition of returned products.

3. Collaborate with Suppliers

Collaboration with suppliers is crucial in a closed-loop supply chain. This involves working together to ensure that sustainable materials and processes are used and that high efforts are put into the supply chain network design.

4. End-of-Life Management

Properly managing the end-of-life stage of products is crucial in a CLSC. This includes recycling, refurbishing, and remanufacturing products to keep them in use for as long as possible.

5. Transparency and Traceability:

Having transparency and traceability throughout the supply chain management is important for both businesses and consumers. This can help identify any potential issues or opportunities for improvement and build trust with consumers.

6. Continuous Improvement:

Closed loop supply chain management is an ongoing process that requires continuous evaluation and improvement. Regularly collecting data and feedback, analyzing processes, and implementing changes are essential for sustainability and efficiency.

In addition to these best practices, it is important for businesses to have a clear understanding of their environmental impact and actively work towards reducing it. This can be achieved through implementing practices such as using renewable energy, reducing waste, and minimizing the use of non-recyclable materials.

Automating Closed Loop Supply Chains

Automation in a closed-loop supply chain management system can amplify its existing benefits and introduce new ones:

1. Increased Efficiency

Automation streamlines processes, reducing manual intervention and increasing the speed and efficiency of the recovery, remanufacturing, and recycling processes.

2. Reduced Errors

Automated systems are less prone to errors compared to manual processes, enhancing the accuracy of recycling or remanufacturing, and ensuring that the maximum value is extracted from each returned product.

3. Real-Time Tracking and Visibility

Automation can provide real-time tracking of products in the reverse flow, giving businesses a clear view of their inventory and allowing for more accurate forecasting and planning.

4. Scalability

Automated systems can easily handle increased volumes of returned products, making them ideal for businesses looking to scale their operations.

5. Sustainability Reporting

Automated systems can provide accurate data on the amount of waste reduced, and resources saved, aiding in sustainability reporting and compliance with environmental regulations.

By automating the CLSC, businesses can not only improve their operations and bottom line but also make a significant contribution towards environmental sustainability.

Challenges of Implementing a Closed Loop Supply Chain

While the benefits of a closed loop supply chain are clear, there are also some challenges associated with its implementation. These include:

1. COMPLEXITY

Managing a CSLP can be complex and requires coordination across various stages and processes, from collection to remanufacturing.

2. COST

Implementing a closed loop supply chain can lead to cost-used products being reused, reconditioned, remanufactured, or recycled. In the long run, it also requires an initial investment in integrated supply chain, technology, and infrastructure.

4. SUPPLY CHAIN VISIBILITY

To efficiently manage a CSLC, businesses need to have visibility and traceability at all stages. This can be challenging when dealing with multiple suppliers or third-party vendors for global supply chain management.

5. CONSUMER BEHAVIOR

Despite the increasing demand for sustainable products, consumer behavior can still pose a challenge for businesses looking to implement a closed loop supply chain. Consumers may not be willing to pay a premium for sustainable products or may not actively participate in recycling programs.

How to Overcome These Challenges?

Businesses must take the following steps to overcome these challenges.

1. COLLABORATION AND PARTNERSHIPS

In order to manage the complexity of a closed loop supply chain, businesses can collaborate with other organizations or form partnerships with suppliers and third-party vendors.

2. TECHNOLOGY AND INNOVATION

Investing in technology and innovative solutions can help streamline processes and improve visibility in a closed-loop supply chain. This can include implementing tracking systems, supply chain analysis tools, a well-designed supply chain mapping, introducing technologies like blockchain in supply chain management, considering advanced mythologies such as agile supply chain or lean supply chain management, and automation.

3. EDUCATION AND AWARENESS

Businesses can also educate consumers about the benefits of sustainable products and recycling practices. This can be done through marketing campaigns or by partnering with organizations that promote sustainability.

4. INCENTIVES

Offering incentives to consumers for participating in recycling programs or purchasing sustainable products can help drive behavior change and increase demand for CLSC products. This can include discounts, loyalty programs, or rewards.

5. CONTINUOUS IMPROVEMENT

Implementing a continuous improvement mindset within the organization is crucial for the success of a closed-loop supply chain. This involves regularly evaluating processes and making necessary adjustments to improve efficiency and sustainability.

How Does a Closed-Loop Supply Chain Fit into Logistics?

A Closed-Loop Supply Chain (CLSC) seamlessly integrates into the broader scope of logistics, transforming traditional, linear models into dynamic, circular systems. In conventional logistics, goods travel a one-way path from the manufacturer to the customer. However, CLSC introduces the concept of reverse logistics, which may use 3PL and 4PL logistics systems, wherein products journey back to their origin, either for refurbishment, recycling, or safe disposal.

- This circular approach not only adds a new dimension to logistics management but also provides opportunities for cost savings, resource optimization, and enhanced customer engagement.

- CLSC aligns perfectly with the growing trend towards environmental responsibility – a paradigm shift in logistics that not only fulfills business objectives but also addresses global ecological concerns.

Examples of Top 5 Closed Loop Supply Chain Companies

Several companies have successfully implemented closed loop supply chains and serve as exemplary models in the field of sustainability.

1. APPLE CLOSED-LOOP SUPPLY CHAIN:

Apple is a prominent example of a company that practices CSLC management. The company has committed to becoming 100% carbon-neutral and is making progress towards this goal through various initiatives, such as using recycled materials in its products and offering trade-in programs for customers.

2. DELL CLOSED-LOOP SUPPLY CHAIN

Dell has been recognized for its efforts in creating a sustainable supply chain using the SCOR Model, using recycled materials in its product packaging, managing supply chain risks, and offering an extensive hardware take-back program. The company’s sustainability initiatives also extend to reducing waste in its production processes through continuous improvement strategies.

3. PATAGONIA CLOSED-LOOP SUPPLY CHAIN

An outdoor apparel company, Patagonia, is renowned for its commitment to sustainability. The company has implemented a CSLC through measures like repairing and recycling its products and sourcing materials responsibly.

4. TESLA CLOSED-LOOP SUPPLY CHAIN

Tesla is another example of a company operating a CLSC. The company recycles the majority of the components of its electric vehicles, including the batteries, thus minimizing waste and promoting sustainability.

These companies demonstrate that a CLSC is not only viable but can also confer substantial benefits in terms of both financial performance and environmental impact.

Conclusion

Implementing a closed-loop supply chain can bring numerous benefits to businesses, including cost savings, improved environmental sustainability, and increased customer satisfaction. However, it also comes with its challenges, such as the need for efficient reverse logistics and collaboration with suppliers. As seen in the examples, companies that have successfully implemented a closed loop supply chain have reaped significant rewards and demonstrated their commitment to sustainability. So, businesses looking to enhance their environmental performance while staying competitive should seriously consider implementing a CLSC. By doing so, they can contribute to a more circular economy and make a positive impact on the planet. In an effort to preserve natural resources, many businesses are turning to open-loop recycling, a type of recycling where products and materials are transformed into new items, albeit not necessarily of the same kind, using the best supply chain planning processes and effective methods for waste reduction and resource efficiency.

Frequently Asked Questions

Q1: What is a closed-loop supply chain (CLSC)?

A closed-loop supply chain integrates forward and reverse flows to recover value through reuse, refurbishment, remanufacturing, and recycling, cutting waste and supporting circularity.

Q2: How does a closed-loop supply chain differ from the circular economy?

CLSC is a practical, operational model for product and material flows. The circular economy is a broader system covering sharing, repair, refurbishment, and recycling to eliminate waste.

Q3: What are the key stages in a CLSC life cycle?

Design, manufacturing, distribution, consumption, reuse & refurbishment, and recycling—enabled by innovation, collaboration, education, technology, policy, and shifting consumer demand.

Q4: Why is product design critical for CLSC?

Design for circularity enables durability, repairability, disassembly, and standardised parts—simplifying refurbishment and recycling while extending product life.

Q5: What role does reverse logistics play?

It manages returns from customers back to producers or partners for inspection, reuse, refurbishment, remanufacturing, or recycling, enabling material recovery.

Q6: Which best practices improve CLSC management?

Design for sustainability, strong reverse logistics, supplier collaboration, end-of-life planning, transparent tracking, and continuous improvement with clear KPIs.

Q7: How can automation strengthen CLSC performance?

Automation speeds processing, reduces errors, scales returns, and provides real-time visibility and data for forecasting and sustainability reporting.

Q8: What are common implementation challenges?

Complex coordination, upfront costs, limited multi-party visibility, and inconsistent consumer participation in take-back or recycling programmes.

Q9: How can businesses overcome these challenges?

Build partnerships, invest in tracking and analytics, educate customers, offer incentives for returns, and commit to continuous improvement.

Q10: How does a CLSC fit within logistics?

It extends outbound logistics with reverse flows—often via 3PL/4PL partners—improving resource use, cost control, and environmental outcomes.

Q11: Are there real-world examples?

Apple, Dell, Patagonia, and Tesla run programmes to recover materials and refurbish or recycle components, demonstrating both financial and environmental benefits.

Q12: Which metrics support transparency?

Return rates, refurbishment yield, recycled content, processing time, and reductions in carbon and waste, with data shared across stakeholders.