Why Are There Different Types of Supply Chains?

Supply chain management controls the entire network of entities, tasks, resources, and technologies involved in developing and marketing goods and services, from procuring raw materials to delivering final goods to the consumer. Each step in this process is a part of the supply chain. It is a complicated system that requires careful supply chain management to ensure effectiveness and efficiency.

From Farm to Factory: Supply Chains Across Different Sectors

The supply chain plays an important role in organizations and companies, ranging from marketing and manufacturing to agriculture and technology.

- They control how efficiently products can be supplied to markets using different technologies.

- Modern software has significantly advanced supply chain management.

- Machine learning, data analytics, and artificial intelligence (AI) are crucial in demand forecasting, inventory management, improving manufacturing, and procurement management processes.

- The supply chain is also linked with logistics management, including transportation, inventory, and delivery of products.

Therefore, different types of supply chains are designed to ensure end-to-end efficiency and customer satisfaction.

Purpose of Various Types of Supply Chains

The different types of supply chains and their specific purposes play a crucial role in businesses by optimizing operations, increasing efficiency, and lowering production costs. The diversity in types of supply chains arises due to varying needs, operational complexities, and the company’s specific goals such as company size, product nature, industry, and market demands.

Below are several key aspects that contribute to the development of various types of supply chains:

1. Large and Small Businesses

This is one aspect that influences the types of supply chains. For example, larger businesses that enter fast-changing markets acquire strategic supply chains for flexibility, while small companies often rely on linear supply chains.

2. Efficiency and Cost Optimization

These two factors also influence the types of supply chains. Companies seeking to reduce costs may choose direct or collaborative supply chains to minimize intermediaries.

3. E-commerce Businesses

E-commerce businesses require fast customer delivery services and typically opt for direct supply chains.

4. Automotive Businesses

The automotive industry needs to manage multiple suppliers simultaneously. In this case, complex supply chains help companies optimize operations, stay competitive, and improve efficiency.

5. Sustainability and Compliance Needs

Companies with environmental or social responsibility goals implement green supply chains to reduce waste, carbon emissions, and ensure ethical sourcing.

6. Global Expansion

Multinational corporations utilize global or extended supply chains to manage operations across borders and serve diverse markets.

7. Innovation & Personalization Demands

Businesses requiring frequent product updates and customization often opt for flexible or hybrid supply chains to balance agility and efficiency.

8. Digital Transformation

Digitally driven businesses use digital supply chains that leverage AI, IoT, and big data for predictive analytics, real-time tracking, and automation.

Key Features of Different Types of Supply Chains

| Aspect | Type of Supply Chain | Purpose | Best For | Unique Characteristics |

| Large Businesses | Strategic/Agile Supply Chain | Offers flexibility and responsiveness in dynamic markets | Enterprises with large-scale, fast-moving operations | Enables quick adaptation to market changes and customer demand |

| Small Businesses | Linear Supply Chain | Simple, step-by-step flow from supplier to customer | Startups and small businesses | Cost-effective and easy to manage, but limited flexibility |

| Cost-Focused Operations | Direct Supply Chain | Minimizes intermediaries to reduce operational and logistics costs | Cost-sensitive businesses | Shortens lead times and enhances supplier relationships |

| Collaborative Operations | Collaborative Supply Chain | Encourages partnership with suppliers and stakeholders | Companies aiming for joint efficiency gains | Improves visibility and coordination across the supply chain |

| E-commerce Businesses | Direct-to-Consumer (D2C) Chain | Prioritizes speed and convenience in last-mile delivery | Online retailers and marketplaces | Relies heavily on tech-driven logistics and automation |

| Automotive Industry | Complex/Global Supply Chain | Coordinates multiple suppliers and manufacturing units | Automotive and aerospace sectors | Emphasizes multi-tier supplier management and quality control |

| Demand-Driven Environments | Lean Supply Chain | Minimizes waste and aligns production with real-time demand | Retail, electronics, and fashion | Focuses on just-in-time inventory and rapid demand forecasting |

| Innovation-Driven Companies | Flexible/Responsive Supply Chain | Quickly adapts to innovation cycles and custom requirements | Tech and consumer electronics firms | Allows frequent product updates and customization |

| Global Enterprises | Global/Extended Supply Chain | Supports international sourcing and global market delivery | Multinational corporations | Involves complex logistics, compliance, and risk mitigation strategies |

Types of Supply Chain Management Based on Functional Purpose

Every business has unique operational needs, product flows, and market pressures. These variations require tailored supply chain strategies to maximize efficiency, responsiveness, and sustainability.

The table below outlines various types of supply chains, their functional purpose, and where they are best applied, helping organizations choose the right model based on their industry, scale, and goals.

| Type of Supply Chain | Purpose & Application |

| Lean Supply Chain |

|

| Agile Supply Chain |

|

| Flexible/Responsive Supply Chain |

|

| Green/Sustainable Supply Chain |

|

| Global/Extended Supply Chain |

|

| Hybrid Supply Chain |

|

| Digital Supply Chain |

|

| Cold Chain |

|

| Service Supply Chain |

|

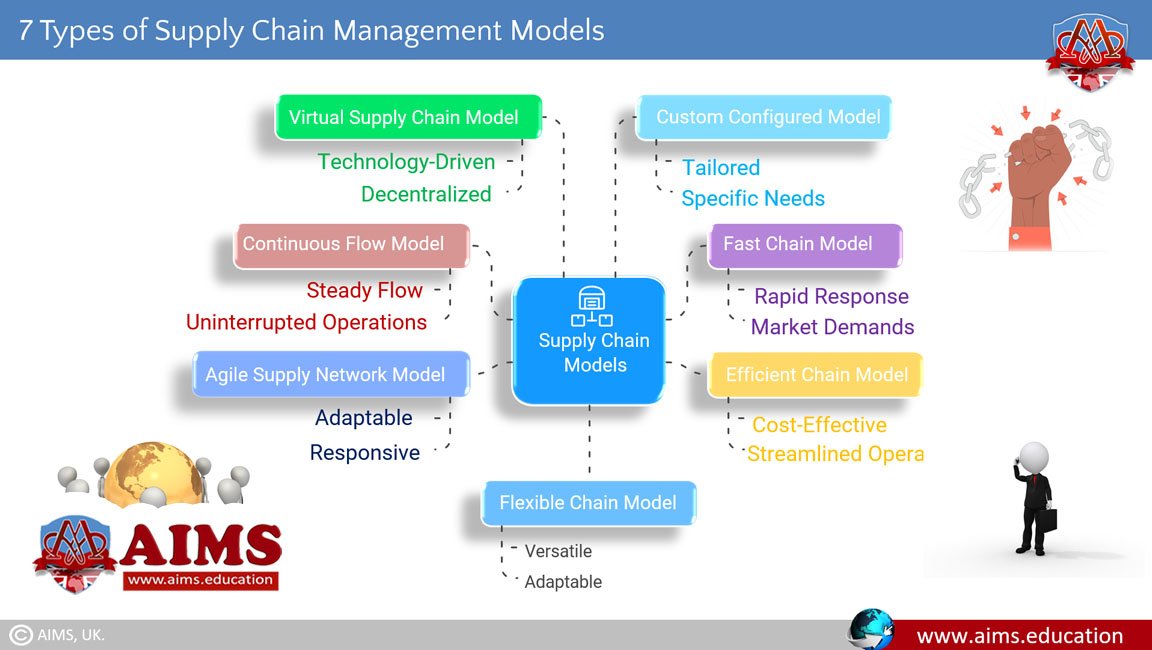

7 Types of Supply Chain Management Models

As discussed earlier, every supply chain business has unique features and requirements, which is why different operating types of supply chains have been developed. Supply chain graduates study supply chain management in detail during logistics management and supply chain diploma or MBA degree in supply and logistics management to develop the skills needed to effectively manage supply chain processes.

These types of supply chain management models demonstrate how materials and production are accomplished and delivered.

1. Continuous Flow Model (CFM)

CFM is intended for supply chain stability and consistency. It is highly effective in businesses with steady and predictable product demand.

a. Applicability:

Well-suited for businesses with continuous manufacturing processes, such as food producers or automobile manufacturers.

b. Example:

A dairy company that continuously produces milk to meet the demand from consumers.

c. Advantages:

Reduces the risks associated with the supply chain management, such as stockouts, enhances efficiency, and ensures a stable production rate.

d. Disadvantages:

Lacks flexibility in adapting to unexpected demand shifts or supply chain disruptions.

e. Real-World Case Study:

A good example of the continuous flow model is Coca-Cola. The company has a highly predictable demand for its products, which allows for a continuous flow of production. The company uses a continuous flow model to maintain steady production and distribution, ensuring product availability in global markets.

2. Fast Chain Model (FCM)

FCM is designed for businesses with short product life cycles, fast-changing demands, and a strong need for rapid responsiveness.

a. Applicability:

Ideal for fashion retailers, electronics manufacturers, or businesses handling seasonal or trend-driven products.

b. Example:

Fashion retailers that quickly design, manufacture, and deliver clothing driven by new trends.

c. Advantages:

Allows swift adaptation to market trends, minimizes the risk of overstocking, and aligns with shifting consumer preferences.

d. Disadvantages:

May incur higher costs.

e. Real-World Case Study:

Zara, the Spanish fashion retailer, is a prime example of the Fast Chain Model. Zara’s supply chain is designed to quickly respond to the latest fashion trends, producing and distributing new collections to stores in as little as two weeks. This enables Zara to offer trendy items that match current consumer demand, minimizing excess inventory.

3. Efficient Chain Model (ECM)

ECM in supply chain management emphasizes cost optimization by streamlining logistics and SCM operations.

a. Applicability:

Suitable for large-scale manufacturing processes that produce high volumes and low-cost products.

b. Example:

Large consumer goods manufacturers focus on high-volume production to maintain competitive pricing while ensuring quality.

c. Advantages:

It enhances operational efficiency, lowers costs, and reduces waste.

d. Disadvantages:

Less flexible in responding to changes in supply chain disruptions or market demand.

e. Real-World Case Study:

Walmart, as an example, uses the Efficient Chain Model by leveraging its massive scale and cost-efficient operations. By implementing just-in-time inventory systems and negotiating favorable contracts with suppliers, Walmart is able to pass on cost savings to consumers while maintaining efficiency in its supply chain.

4. Agile Supply Network Model (ASNM)

The Agile Supply Network Model is designed to quickly adapt to market changes and growing customer needs, emphasizing responsiveness and flexibility.

a. Applicability:

An ideal model for businesses experiencing high variability in customer demand, such as those in the technology and fashion sectors.

b. Example:

Technology companies that need rapid adjustments to innovations and changing consumer preferences.

c. Advantages:

Enables swift responses to market shifts, delivers excellent customer service, and handles unpredictability effectively.

d. Disadvantages:

Often results in higher operational costs and requires advanced forecasting and response systems.

e. Real-World Case Study:

Apple exemplifies the Agile Supply Network Model. As a technology company, Apple constantly faces rapid changes in consumer demand and technological advancements. Its supply chain is highly responsive, with quick adaptation to new product launches and updates. However, this flexibility comes at a high cost, with Apple’s premium pricing strategies offsetting the higher costs associated with agility.

5. Virtual Supply Chain Model (VSCM)

VSCM leverages digital technologies to share real-time information, enabling continuous collaboration with partners without physical infrastructure. It focuses on data-driven decision-making and flexibility.

a. Applicability:

Ideal for businesses operating in e-commerce or relying on digital networks.

b. Example:

Amazon, an online retailer, uses virtual networks to manage inventory, suppliers, and customer orders.

c. Advantages:

Improves visibility, enhances coordination, and minimizes overhead costs.

d. Disadvantages:

Vulnerable to cybersecurity risks and heavily reliant on robust digital infrastructure.

e. Real-World Case Study:

Amazon is a key example of the Virtual Supply Chain Model. By using advanced digital tools such as cloud computing, Amazon can manage a global supply chain without the need for physical infrastructure. This enables the company to have real-time visibility and coordination across its vast network of suppliers, fulfillment centers, and customers.

6. Custom Configured Model (CCM)

CCM is developed to address specific customer or market needs, enabling businesses to offer personalized products or services.

a. Applicability:

Suitable for companies offering specialized products or services where customization is a primary focus.

b. Example:

Automotive manufacturers that allow customers to customize their vehicles’ features rely on supply chains to efficiently accommodate diverse specifications.

c. Advantages:

Delivers high levels of personalization, boosts customer satisfaction, and improves market diversity.

d. Disadvantages:

It can be more complex to manage and may result in higher costs.

e. Real-World Case Study:

Tesla offers a customized car manufacturing process where customers can choose different features for their vehicles. This model requires a flexible and responsive supply chain to accommodate the vast range of options and configurations available to customers.

7. Flexible Chain Model (FCM)

FCM combines efficiency and agility, allowing businesses to adapt quickly to changes while remaining cost-effective.

a. Applicability:

Ideal for companies experiencing seasonal peaks or requiring frequent adjustments in production levels.

b. Example:

Agricultural businesses that adjust supply chain strategies based on seasonal crop yields.

c. Advantages:

Strikes a balance between cost efficiency and adaptability, handling seasonal variations and demand fluctuations.

d. Disadvantages:

Managing the balance between efficiency and flexibility can be complex.

e. Real-World Case Study:

Coca-Cola is also an example of a Flexible Chain Model when adapting its production to meet demand during peak seasons, such as the holiday season. By adjusting its supply chain strategies, the company can balance cost-efficiency with the flexibility needed to manage seasonal demand.

10 Essential Stages in the Development of Different Types of Supply Chains

- Stage 1: Strategic Planning and Procurement in Supply Chain Management.

- Stage 2: Enhancing Production Efficiency in Supply Chain Operations.

- Stage 3: Inventory Optimization Strategies for Effective Supply Chain Management.

- Stage 4: Distribution and Logistics Optimization in Supply Chain Management.

- Stage 5: Demand Forecasting and Planning in Supply Chain Operations.

- Stage 6: Vendor and Supplier Relationship Management in Supply Chains.

- Stage 7: Risk Management and Building Resilience in Supply Chain Systems.

- Stage 8: Technology Integration for Streamlined Supply Chain Operations.

- Stage 9: Sustainability and Ethical Practices in Modern Supply Chains.

- Stage 10: Effective Customer Relationship Management in Supply Chain Systems.

How to Choose the Right Types of Supply Chains for Your Business?

Choosing the right type of supply chain depends on several factors that vary from business to business.

- For small companies, a simple linear supply chain may be sufficient, as it’s cost-effective and easy to manage.

- Larger businesses, however, need more complex, strategic, or agile supply chains to remain flexible and responsive in fast-moving markets.

- The industry you operate in also plays a crucial role. For example, businesses with global operations, a global supply chain is essential, especially for managing international sourcing and logistics.

The key is to match your business’s size, industry, demand type, and operational goals with the characteristics of the most suitable supply chain. Ultimately, the right choice will help optimize efficiency, reduce costs, and improve customer satisfaction.

Frequently Asked Questions

Q1: What are the main types of supply chains?

The main types include lean, agile, flexible, green, global, hybrid, digital, cold, and service supply chains—each suited for specific industries and goals.

Q2: Why do different supply chain types exist?

Different industries have unique operational goals, cost structures, and market demands. Supply chain types evolve to meet those needs efficiently.

Q3: What is a lean supply chain?

A lean supply chain focuses on minimizing waste and reducing costs while maintaining steady production—ideal for retail, electronics, and fashion sectors.

Q4: What is an agile supply chain?

An agile supply chain emphasizes speed and responsiveness to market changes, making it suitable for fast-moving industries like tech and fashion.

Q5: What is a hybrid supply chain?

A hybrid supply chain combines lean and agile models to balance cost efficiency with flexibility, handling both stable and fluctuating demands.

Q6: What are digital supply chains?

Digital supply chains use AI, IoT, and real-time analytics for automation and visibility—vital for smart manufacturing and e-commerce.

Q7: How do global supply chains operate?

Global supply chains manage sourcing, production, and logistics across borders to serve international markets efficiently and compliantly.

Q8: What is a green or sustainable supply chain?

A green supply chain integrates sustainability by minimizing emissions, waste, and promoting ethical sourcing aligned with ESG objectives.

Q9: What are the stages of supply chain development?

There are ten key stages—from strategic planning and procurement to sustainability and customer relationship management.

Q10: How can businesses choose the right supply chain type?

Businesses should align supply chain type with size, industry, demand patterns, and sustainability goals to balance cost and responsiveness.